Where are Toyotas made, and how does this impact your choice in Boise? Toyota vehicles are manufactured in various locations across North America, including the United States, showcasing the brand’s commitment to the American economy. Discover the specific plants and models made in each location, plus learn about the benefits of choosing a Toyota from millertoyota.net, with Toyota reliability and exceptional service.

1. What Toyota Models Are Made in the USA?

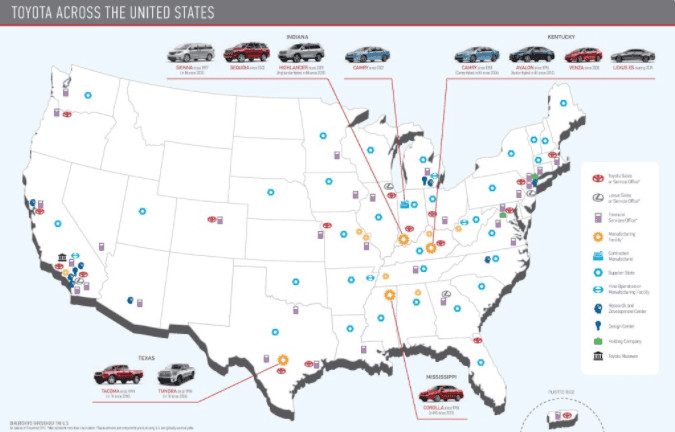

Toyota produces a variety of models in the United States, demonstrating its significant investment in American manufacturing. Among the vehicles manufactured in North American facilities are the Avalon, Corolla, Camry, Highlander, RAV4, Tundra, Sequoia, and Tacoma. These models are produced in plants located in Kentucky, Indiana, Mississippi, California, and Texas, contributing to local economies and ensuring a steady supply of vehicles for the American market. According to Toyota’s official website, these U.S. plants adhere to the highest quality standards.

2. Where are Toyota’s Manufacturing Plants Located in the United States?

Toyota’s manufacturing footprint in the United States spans several states, each playing a crucial role in the production of various models. Key locations include:

- Kentucky: Toyota Motor Manufacturing Kentucky, Inc. (TMMK) in Georgetown.

- Indiana: Toyota Motor Manufacturing Indiana, Inc. (TMMI) in Princeton.

- Mississippi: Toyota Motor Manufacturing Mississippi (TMMMS) in Blue Springs.

- Texas: Toyota Motor Manufacturing Texas, Inc. (TMMTX) in San Antonio.

Aerial view of Toyota Motor Manufacturing Kentucky, Inc.These plants are strategically located to optimize production efficiency and distribution across the country.

Aerial view of Toyota Motor Manufacturing Kentucky, Inc.These plants are strategically located to optimize production efficiency and distribution across the country.

3. What Is Toyota Motor Manufacturing Kentucky (TMMK) Known For?

Toyota Motor Manufacturing Kentucky, Inc. (TMMK), established in 1986, is Toyota’s first wholly-owned U.S. manufacturing plant and the largest outside of Japan. TMMK is known for producing popular models such as the Avalon, Avalon Hybrid, Camry, and Camry Hybrid. The plant has a long-standing reputation for quality and innovation in automotive manufacturing. TMMK produced 504,213 vehicles in 2013 alone. According to Toyota’s official data, TMMK is the largest Toyota manufacturing plant outside Japan.

4. What Vehicles Does Toyota Motor Manufacturing Indiana (TMMI) Produce?

Toyota Motor Manufacturing Indiana, Inc. (TMMI) primarily manufactures SUVs and minivans for the American market. Established in 1996, TMMI is responsible for producing the Highlander, Sequoia, and Sienna models. The plant has evolved from initially focusing on full-size pickup trucks to specializing in SUVs and minivans to meet changing consumer demands. In 2013, TMMI produced up to 299,820 vehicles. According to recent reports, TMMI is expanding its production capabilities to include hybrid vehicles.

5. What Is the Role of Toyota Motor Manufacturing Mississippi (TMMMS)?

Toyota Motor Manufacturing Mississippi (TMMMS) plays a vital role in Toyota’s North American production strategy by focusing on manufacturing the popular Corolla model. Opened in 2011, TMMMS was initially planned to produce the Highlander but later shifted to Corolla production. TMMMS contributes significantly to Toyota’s overall production volume, with 158,647 vehicles produced in 2013. The plant’s strategic location in Blue Springs, Mississippi, enhances Toyota’s supply chain efficiency.

6. What Kind of Trucks Are Made at Toyota Motor Manufacturing Texas (TMMTX)?

Toyota Motor Manufacturing Texas, Inc. (TMMTX) specializes in manufacturing Toyota’s full-size pickup trucks, including the Tacoma and Tundra. Acquired by Toyota in 2003, TMMTX is located in San Antonio, Texas, and is a key facility for truck production in North America. In 2013, TMMTX produced 228,983 vehicles. According to Toyota’s official press releases, TMMTX is committed to producing high-quality trucks for the American market.

7. How Does Toyota Ensure Quality Control in Its American Manufacturing Plants?

Toyota ensures quality control in its American manufacturing plants through rigorous processes and a commitment to continuous improvement. These measures include:

-

Standardized Production Systems: Implementing the Toyota Production System (TPS) to ensure efficiency and quality.

-

Employee Training: Providing extensive training to employees on quality control procedures.

-

Regular Inspections: Conducting frequent inspections at every stage of the manufacturing process.

-

Advanced Technology: Utilizing advanced technology and automation to minimize errors and improve precision.

These efforts ensure that every vehicle meets Toyota’s high standards for reliability and performance.

8. What Are the Economic Benefits of Toyota Manufacturing in the USA?

Toyota’s manufacturing operations in the USA generate significant economic benefits, including:

- Job Creation: Providing thousands of direct and indirect jobs in manufacturing, supply chain, and related industries.

- Investment in Local Economies: Contributing to local economies through taxes, supplier contracts, and community development programs.

- Increased Manufacturing Output: Boosting the overall manufacturing output of the United States.

- Technological Advancement: Promoting technological advancement through the adoption of innovative manufacturing processes.

According to a recent economic impact study, Toyota’s U.S. operations contribute billions of dollars to the national economy annually.

9. What is Toyota’s Commitment to Sustainable Manufacturing Practices in the USA?

Toyota is committed to sustainable manufacturing practices in the USA, focusing on reducing environmental impact and promoting resource conservation. Key initiatives include:

- Reducing Waste: Implementing programs to reduce waste and recycle materials throughout the manufacturing process.

- Conserving Energy: Utilizing energy-efficient technologies and practices to minimize energy consumption.

- Lowering Emissions: Reducing greenhouse gas emissions through the adoption of cleaner energy sources and improved processes.

- Water Conservation: Implementing water conservation measures to reduce water usage in manufacturing operations.

Toyota’s commitment to sustainability is reflected in its environmental performance metrics, which show continuous improvement in reducing its environmental footprint.

10. Why Should Boise Residents Choose a Toyota from millertoyota.net?

Boise residents should choose a Toyota from millertoyota.net for several compelling reasons:

- Wide Selection: Access to a wide selection of new and used Toyota models, including those manufactured in the USA.

- Competitive Pricing: Offering competitive pricing and financing options to fit various budgets.

- Exceptional Service: Providing exceptional customer service and expert maintenance and repair services.

- Genuine Parts: Using genuine Toyota parts to ensure the reliability and longevity of your vehicle.

At millertoyota.net, you’ll find the perfect Toyota to meet your needs, backed by a commitment to quality and customer satisfaction.

11. How Does Buying a Toyota Made in the USA Support the American Economy?

Buying a Toyota made in the USA directly supports the American economy by:

- Creating Jobs: Supporting American jobs in manufacturing, engineering, and related industries.

- Boosting Local Economies: Contributing to local economies through taxes, supplier contracts, and community development programs.

- Reducing Trade Deficit: Decreasing the trade deficit by increasing domestic production and reducing reliance on imports.

- Promoting Innovation: Encouraging innovation and technological advancement in the American automotive industry.

By choosing a Toyota made in the USA, you are investing in the future of American manufacturing.

12. What Are the Benefits of the Toyota Production System (TPS) Implemented in US Plants?

The Toyota Production System (TPS), implemented in Toyota’s US plants, offers several key benefits:

- Enhanced Efficiency: Streamlining production processes to eliminate waste and improve efficiency.

- Improved Quality: Ensuring consistent quality through standardized procedures and rigorous quality control measures.

- Reduced Costs: Lowering production costs by minimizing waste and optimizing resource utilization.

- Increased Flexibility: Enhancing the ability to adapt to changing market demands and customer preferences.

TPS is a cornerstone of Toyota’s manufacturing philosophy, driving continuous improvement and delivering high-quality vehicles to customers.

13. How Does Toyota’s Manufacturing Presence in the USA Benefit Local Communities?

Toyota’s manufacturing presence in the USA provides numerous benefits to local communities:

- Economic Development: Stimulating economic development through job creation and investment in local businesses.

- Community Engagement: Supporting local schools, charities, and community organizations through philanthropic initiatives.

- Infrastructure Improvement: Contributing to infrastructure improvements, such as roads and utilities, to support manufacturing operations.

- Skills Development: Providing training and skills development opportunities for local residents, enhancing their career prospects.

Toyota is committed to being a responsible corporate citizen and making a positive impact on the communities where it operates.

14. What Role Do American Suppliers Play in Toyota’s US Manufacturing Operations?

American suppliers play a critical role in Toyota’s US manufacturing operations by providing:

- Component Manufacturing: Manufacturing a wide range of components, from engines and transmissions to interior parts and electronics.

- Material Supply: Supplying raw materials, such as steel, aluminum, and plastics, used in vehicle production.

- Logistics Support: Providing logistics and transportation services to ensure a smooth and efficient supply chain.

- Technological Innovation: Contributing to technological innovation through the development of advanced materials and manufacturing processes.

Toyota partners with hundreds of American suppliers, supporting thousands of additional jobs and contributing to the growth of the US manufacturing sector.

15. How Does Toyota Train Its Employees in American Manufacturing Plants?

Toyota invests heavily in training its employees in American manufacturing plants to ensure they have the skills and knowledge to perform their jobs effectively. Training programs include:

- On-the-Job Training: Providing hands-on training in specific manufacturing processes and quality control procedures.

- Classroom Instruction: Offering classroom-based instruction in topics such as safety, teamwork, and problem-solving.

- Technical Training: Providing technical training in areas such as robotics, automation, and advanced manufacturing technologies.

- Leadership Development: Offering leadership development programs to prepare employees for management and supervisory roles.

Toyota’s comprehensive training programs empower employees to continuously improve their skills and contribute to the company’s success.

16. What Technologies Are Used in Toyota’s American Manufacturing Facilities?

Toyota’s American manufacturing facilities utilize a range of advanced technologies to enhance efficiency, quality, and sustainability:

- Robotics and Automation: Employing robots and automated systems to perform repetitive tasks and improve precision.

- Advanced Materials: Utilizing advanced materials, such as lightweight alloys and composites, to improve vehicle performance and fuel efficiency.

- 3D Printing: Using 3D printing technology to create prototypes, tooling, and custom parts.

- Data Analytics: Employing data analytics to optimize production processes, predict maintenance needs, and improve overall efficiency.

These technologies enable Toyota to produce high-quality vehicles with minimal waste and environmental impact.

17. How Does Toyota Measure the Success of Its American Manufacturing Operations?

Toyota measures the success of its American manufacturing operations through a variety of key performance indicators (KPIs), including:

- Production Volume: Tracking the number of vehicles produced per plant and overall production capacity.

- Quality Metrics: Monitoring quality metrics, such as defect rates and customer satisfaction scores.

- Efficiency Measures: Measuring efficiency measures, such as labor productivity, energy consumption, and material waste.

- Safety Performance: Tracking safety performance metrics, such as accident rates and near-miss incidents.

Toyota uses these KPIs to identify areas for improvement and drive continuous progress in its manufacturing operations.

18. How Does Toyota Adapt to Changing Consumer Preferences in Its US Manufacturing Plants?

Toyota adapts to changing consumer preferences in its US manufacturing plants through:

- Flexible Manufacturing Systems: Implementing flexible manufacturing systems that can quickly adapt to changes in product design and production volume.

- Market Research: Conducting market research to understand consumer preferences and anticipate future trends.

- Customer Feedback: Gathering customer feedback through surveys, focus groups, and social media to identify areas for improvement.

- Continuous Improvement: Embracing a culture of continuous improvement and innovation to meet evolving customer needs.

Toyota’s ability to adapt to changing consumer preferences is a key factor in its long-term success in the US market.

19. What Are Some of the Challenges Facing Toyota’s American Manufacturing Operations?

Toyota’s American manufacturing operations face several challenges, including:

- Increasing Competition: Facing increasing competition from other automakers, both domestic and international.

- Rising Costs: Managing rising costs of labor, materials, and energy.

- Regulatory Compliance: Complying with increasingly stringent environmental and safety regulations.

- Supply Chain Disruptions: Mitigating the impact of supply chain disruptions caused by natural disasters, trade disputes, and other factors.

Toyota is addressing these challenges through strategic investments, operational improvements, and collaboration with suppliers and government agencies.

20. What Are Toyota’s Future Plans for Manufacturing in the USA?

Toyota’s future plans for manufacturing in the USA include:

- Expanding Production Capacity: Expanding production capacity to meet growing demand for Toyota vehicles.

- Investing in New Technologies: Investing in new technologies, such as electric vehicle production, to stay ahead of the curve.

- Enhancing Sustainability: Enhancing sustainability through the adoption of cleaner energy sources and more efficient manufacturing processes.

- Strengthening Community Partnerships: Strengthening partnerships with local communities to support economic development and social responsibility.

Toyota is committed to maintaining a strong manufacturing presence in the USA and contributing to the country’s economic prosperity.

21. Where Can Boise Residents Find More Information About Toyota Vehicles?

Boise residents can find more information about Toyota vehicles at millertoyota.net. Our website offers:

- Detailed Model Information: Comprehensive details on all new and used Toyota models.

- Inventory Listings: Up-to-date inventory listings with photos, specifications, and pricing.

- Service Information: Information on Toyota service and maintenance, including scheduling options.

- Contact Information: Easy access to our contact information, including phone number, address, and online contact form.

22. How Does millertoyota.net Ensure Customer Satisfaction?

At millertoyota.net, we ensure customer satisfaction through:

- Knowledgeable Staff: Employing knowledgeable and friendly staff who are dedicated to helping customers find the perfect vehicle.

- Transparent Pricing: Providing transparent pricing and financing options with no hidden fees.

- Quality Service: Offering quality service and maintenance with certified technicians and genuine Toyota parts.

- Customer Support: Providing exceptional customer support and addressing any concerns promptly and effectively.

23. What Financing Options Are Available at millertoyota.net for Toyota Vehicles?

Millertoyota.net offers a variety of financing options to help Boise residents purchase their dream Toyota, including:

- Loans: Competitive loan rates and terms through Toyota Financial Services and other lenders.

- Leases: Flexible lease options with low monthly payments and various mileage allowances.

- Special Programs: Special financing programs for first-time buyers, military personnel, and recent college graduates.

- Online Application: Easy online application process for pre-approval and quick financing decisions.

24. What Service and Maintenance Options Are Available for Toyota Owners in Boise?

Toyota owners in Boise can take advantage of a wide range of service and maintenance options at millertoyota.net, including:

- Routine Maintenance: Routine maintenance services, such as oil changes, tire rotations, and brake inspections.

- Major Repairs: Major repair services, such as engine repairs, transmission repairs, and collision repairs.

- Genuine Parts: Using genuine Toyota parts to ensure the reliability and longevity of your vehicle.

- Certified Technicians: Employing certified technicians who are trained to service all Toyota models.

25. How Can I Schedule a Test Drive at millertoyota.net?

Scheduling a test drive at millertoyota.net is easy and convenient:

- Online Scheduling: Schedule a test drive online through our website at your convenience.

- Phone Scheduling: Call us to schedule a test drive with one of our friendly sales representatives.

- Walk-Ins: Visit our dealership and schedule a test drive in person.

26. What Are the Benefits of Choosing Genuine Toyota Parts for My Vehicle?

Choosing genuine Toyota parts for your vehicle offers several benefits:

- Superior Quality: Genuine Toyota parts are manufactured to the highest standards of quality and durability.

- Perfect Fit: Genuine Toyota parts are designed to fit your vehicle perfectly, ensuring optimal performance and reliability.

- Warranty Coverage: Genuine Toyota parts are backed by a warranty, providing peace of mind and protection against defects.

- Maintained Value: Using genuine Toyota parts helps maintain the value of your vehicle and ensures it continues to perform at its best.

27. How Can I Contact millertoyota.net for More Information?

You can contact millertoyota.net for more information through the following channels:

- Address: 208 N Maple Grove Rd, Boise, ID 83704, United States

- Phone: +1 (208) 376-8888

- Website: millertoyota.net

- Online Contact Form: Fill out our online contact form on our website and we will respond promptly.

28. What Makes Toyota Vehicles Reliable?

Toyota vehicles are renowned for their reliability due to:

- Stringent Manufacturing Processes: Toyota’s meticulous manufacturing processes and quality control.

- High-Quality Components: The use of durable, high-quality parts.

- Engineering Excellence: Advanced engineering and design.

- Regular Maintenance: Emphasis on regular maintenance which prolongs vehicle life.

29. How Does Toyota Incorporate Customer Feedback Into Vehicle Design and Manufacturing?

Toyota actively incorporates customer feedback through:

- Surveys and Focus Groups: Conducting surveys and focus groups to gather opinions.

- Social Media Monitoring: Monitoring social media to identify common issues and preferences.

- Dealership Feedback: Collecting feedback from dealerships to understand customer needs.

- Direct Engagement: Engaging with customers directly at events and through online forums.

30. What Are the Environmental Benefits of Driving a Toyota Hybrid?

Driving a Toyota hybrid offers several environmental benefits:

- Reduced Emissions: Lower greenhouse gas emissions.

- Improved Fuel Economy: Increased fuel efficiency.

- Lower Fuel Consumption: Reduced reliance on fossil fuels.

- Sustainable Driving: Contributes to a more sustainable environment.

Considering a Toyota? Visit millertoyota.net to explore our wide selection of models, learn about our exceptional service options, and discover the perfect vehicle for your needs in Boise. Contact us today and drive away in your dream Toyota. Address: 208 N Maple Grove Rd, Boise, ID 83704, United States. Phone: +1 (208) 376-8888.