Who Manufactures Toyota vehicles, and where are they made? Toyota vehicles are primarily manufactured by Toyota Motor Corporation, a Japanese multinational automotive manufacturer. This guide explores Toyota’s global manufacturing footprint and focuses on its North American operations, particularly Miller Toyota in Boise, Idaho.

1. Who is the Primary Manufacturer of Toyota Vehicles?

Toyota Motor Corporation is the primary manufacturer of Toyota vehicles. Founded in 1937, Toyota Motor Corporation is a global automotive giant recognized for its commitment to quality, reliability, and innovation. The company produces a wide range of vehicles, from compact cars to trucks and SUVs, and also manufactures automotive parts and accessories.

1.1. What is Toyota Motor Corporation Known For?

Toyota Motor Corporation is known for pioneering manufacturing processes, like the Toyota Production System (TPS), which emphasizes efficiency and continuous improvement. This commitment to excellence has made Toyota one of the world’s leading automotive manufacturers. According to Forbes, Toyota was ranked among the top 100 of the world’s best companies in 2023.

1.2. Where is Toyota Motor Corporation Headquartered?

Toyota Motor Corporation is headquartered in Toyota City, Japan. The company has manufacturing plants and facilities located across the globe, including significant operations in North America. These facilities play a vital role in producing vehicles for local and international markets.

2. Where Does Toyota Manufacture Its Vehicles?

Toyota manufactures its vehicles in several locations worldwide, including Japan, North America, Europe, and Asia. This global presence enables Toyota to cater to diverse markets and consumer needs efficiently.

2.1. What is Toyota’s Manufacturing Presence in North America?

Toyota has a strong manufacturing presence in North America, with plants located in the United States, Canada, and Mexico. These facilities produce a significant portion of the vehicles sold in North America. As of 2023, Toyota’s investment in North American manufacturing facilities exceeded $28 billion, and the company directly employs over 47,000 people in the region. Toyota’s commitment to local production helps support the North American economy while ensuring timely delivery of vehicles to dealerships like Miller Toyota in Boise, Idaho.

2.2. What Toyota Models are Manufactured in North America?

Several popular Toyota models are manufactured in North America, including:

- Camry

- Corolla

- Highlander

- Tacoma

- Tundra

- RAV4

2.3. How Does Local Manufacturing Benefit Customers?

Manufacturing vehicles locally allows Toyota to respond more quickly to market demands and customer preferences. It also reduces transportation costs and import duties, which can translate to more competitive pricing for consumers. Dealerships like Miller Toyota in Boise, Idaho, benefit from this efficient supply chain, ensuring a steady inventory of popular models.

3. Which Toyota Models are Manufactured in the USA?

Toyota manufactures several models in the United States, showcasing its commitment to the American market and economy.

3.1. Which US States Host Toyota Manufacturing Plants?

Toyota has manufacturing plants in several U.S. states, including:

- Kentucky

- Indiana

- Mississippi

- Texas

- Alabama

These plants produce a variety of vehicles, from sedans to trucks and SUVs, supporting thousands of jobs and contributing to local economies.

3.2. What are the Key Toyota Manufacturing Plants in the USA?

Some of the key Toyota manufacturing plants in the USA include:

- Toyota Motor Manufacturing Kentucky (TMMK) in Georgetown, Kentucky: One of Toyota’s largest manufacturing facilities globally, producing the Camry, Camry Hybrid, and Avalon.

- Toyota Motor Manufacturing Indiana (TMMI) in Princeton, Indiana: Specializes in SUVs like the Highlander and Sequoia, as well as the Sienna minivan.

- Toyota Motor Manufacturing Mississippi (TMMMS) in Blue Springs, Mississippi: Primarily produces the Corolla.

- Toyota Motor Manufacturing Texas (TMMTX) in San Antonio, Texas: Focuses on trucks, including the Tacoma and Tundra.

- Mazda Toyota Manufacturing USA (MTMUS) in Huntsville, Alabama: A joint venture with Mazda that produces the Corolla Cross.

3.3. What are the Production Capacities of These Plants?

The production capacities of Toyota’s U.S. manufacturing plants vary, but collectively, they can produce over one million vehicles annually. For example, TMMK in Kentucky has the capacity to produce over 500,000 vehicles per year, while TMMTX in Texas can produce over 200,000 trucks annually. This significant production capacity ensures that Toyota can meet the demands of the U.S. market efficiently.

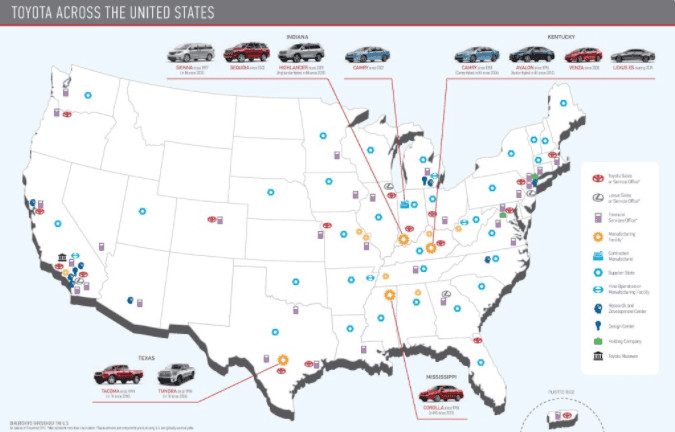

Map of Toyota Operations in the USA

Map of Toyota Operations in the USA

4. What Role Does Toyota Motor Manufacturing Kentucky (TMMK) Play?

Toyota Motor Manufacturing Kentucky (TMMK) plays a crucial role in Toyota’s North American production strategy.

4.1. When was TMMK Established?

TMMK was established in 1986 as Toyota’s first wholly-owned U.S. manufacturing plant. It marked a significant milestone in Toyota’s commitment to local production and investment in the American economy.

4.2. Which Models are Produced at TMMK?

TMMK produces several popular Toyota models, including:

- Camry

- Camry Hybrid

- Avalon

These vehicles are known for their quality, reliability, and fuel efficiency, making them popular choices among consumers.

4.3. What is the Significance of TMMK to Toyota’s Operations?

TMMK is Toyota’s largest manufacturing facility outside of Japan and plays a vital role in meeting the demand for Toyota vehicles in North America. The plant employs thousands of workers and has contributed significantly to the local economy in Kentucky. Its strategic location and advanced manufacturing capabilities make it a key asset for Toyota.

5. What is the Focus of Toyota Motor Manufacturing Indiana (TMMI)?

Toyota Motor Manufacturing Indiana (TMMI) focuses on producing SUVs and minivans for the North American market.

5.1. When was TMMI Established?

TMMI was established in 1996 in Princeton, Indiana. It was initially created to manufacture full-size pickup trucks for the American market.

5.2. Which Models are Manufactured at TMMI?

TMMI manufactures several popular Toyota models, including:

- Highlander

- Sequoia

- Sienna

These vehicles are known for their versatility, comfort, and safety features, making them ideal for families and adventure seekers.

5.3. How Does TMMI Contribute to Toyota’s SUV and Minivan Lineup?

TMMI plays a critical role in Toyota’s SUV and minivan lineup, producing high-quality vehicles that meet the needs of North American consumers. The plant’s advanced manufacturing processes and skilled workforce ensure that these vehicles are built to Toyota’s exacting standards.

6. What is the Role of Toyota Motor Manufacturing Mississippi (TMMMS)?

Toyota Motor Manufacturing Mississippi (TMMMS) primarily focuses on producing the Corolla, a best-selling compact car known for its fuel efficiency and reliability.

6.1. When was TMMMS Established?

TMMMS was established in 2011 in Blue Springs, Mississippi. The plant was initially planned to produce the Toyota Highlander, but production was later shifted to the Indiana plant.

6.2. Why is the Corolla Production Significant for TMMMS?

The Corolla is one of Toyota’s best-selling models worldwide, and its production at TMMMS is significant for several reasons:

- Meeting Demand: TMMMS helps Toyota meet the high demand for the Corolla in North America.

- Economic Impact: The plant provides jobs and supports the local economy in Mississippi.

- Quality Assurance: TMMMS adheres to Toyota’s strict quality control standards, ensuring that the Corolla is built to last.

6.3. How Does TMMMS Support Toyota’s Compact Car Strategy?

TMMMS plays a crucial role in Toyota’s compact car strategy by producing the Corolla, a vehicle that appeals to a wide range of consumers. The plant’s efficient production processes and skilled workforce ensure that the Corolla remains a competitive and popular choice in the compact car segment.

7. What is the Specialization of Toyota Motor Manufacturing Texas (TMMTX)?

Toyota Motor Manufacturing Texas (TMMTX) specializes in producing full-size pickup trucks, including the Tacoma and Tundra.

7.1. When was TMMTX Established?

TMMTX was established in 2003 in San Antonio, Texas. The plant was specifically designed to manufacture Toyota’s full-size pickup trucks for the North American market.

7.2. Which Truck Models are Produced at TMMTX?

TMMTX produces the following truck models:

- Tacoma

- Tundra

These trucks are known for their durability, reliability, and off-road capabilities, making them popular choices among truck enthusiasts and professionals.

7.3. How Does TMMTX Contribute to Toyota’s Truck Lineup?

TMMTX plays a critical role in Toyota’s truck lineup by producing high-quality trucks that meet the demands of North American consumers. The plant’s advanced manufacturing processes and skilled workforce ensure that the Tacoma and Tundra are built to Toyota’s exacting standards. The plant also supports the local economy in Texas, providing jobs and contributing to the region’s growth.

8. How Does Toyota Ensure Quality in Manufacturing?

Toyota ensures quality in manufacturing through the Toyota Production System (TPS), a comprehensive approach that emphasizes efficiency, continuous improvement, and respect for people.

8.1. What is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is a manufacturing philosophy that focuses on eliminating waste, improving efficiency, and ensuring quality at every stage of the production process. Key principles of TPS include:

- Just-in-Time (JIT) Production: Producing only what is needed, when it is needed, and in the amount needed.

- Jidoka (Automation with a Human Touch): Designing equipment to stop automatically when a problem occurs, preventing defects from moving down the production line.

- Continuous Improvement (Kaizen): Encouraging all employees to identify and implement small, incremental improvements to the production process.

- Respect for People: Valuing the contributions of all employees and empowering them to make decisions and solve problems.

8.2. How is TPS Implemented in Toyota’s Manufacturing Plants?

TPS is implemented in Toyota’s manufacturing plants through a variety of practices and tools, including:

- Standardized Work: Creating detailed procedures for each task to ensure consistency and efficiency.

- Visual Management: Using visual cues, such as color-coded labels and charts, to communicate information and identify problems quickly.

- 5S Methodology: Organizing and cleaning the workplace to improve efficiency and safety.

- Problem-Solving Teams: Empowering employees to work together to identify and solve problems.

8.3. What are the Benefits of TPS for Toyota Customers?

The benefits of TPS for Toyota customers include:

- Higher Quality Vehicles: TPS helps Toyota produce vehicles that are more reliable and durable.

- Lower Prices: TPS helps Toyota reduce waste and improve efficiency, which can translate to lower prices for consumers.

- Faster Delivery Times: TPS helps Toyota streamline its production process, which can lead to faster delivery times for customers.

9. How Does Miller Toyota in Boise, Idaho, Fit into Toyota’s Manufacturing and Distribution Network?

Miller Toyota in Boise, Idaho, is a key part of Toyota’s distribution network, connecting the manufacturer with local customers.

9.1. What is the Role of Miller Toyota as a Dealership?

As a dealership, Miller Toyota serves as a bridge between Toyota and its customers in the Boise area. The dealership is responsible for:

- Selling New and Used Toyota Vehicles: Providing customers with a wide selection of Toyota models to choose from.

- Providing Service and Maintenance: Offering expert service and maintenance to keep Toyota vehicles running smoothly.

- Offering Genuine Toyota Parts: Supplying customers with genuine Toyota parts for repairs and maintenance.

- Providing Financing and Insurance Options: Assisting customers with financing and insurance to make their purchase more affordable.

9.2. How Does Miller Toyota Ensure Customer Satisfaction?

Miller Toyota is committed to ensuring customer satisfaction through a variety of measures, including:

- Knowledgeable and Friendly Staff: Employing knowledgeable and friendly staff who are dedicated to providing excellent customer service.

- Transparent Pricing: Offering transparent pricing and no-haggle sales policies.

- Convenient Service Scheduling: Providing convenient service scheduling options, including online booking.

- Comfortable Waiting Areas: Offering comfortable waiting areas with amenities such as Wi-Fi and refreshments.

9.3. How Can Customers in Boise Benefit from Miller Toyota’s Connection to Toyota’s Manufacturing Network?

Customers in Boise benefit from Miller Toyota’s connection to Toyota’s manufacturing network in several ways:

- Access to the Latest Models: Miller Toyota receives the latest Toyota models as soon as they are released, ensuring that customers have access to the newest vehicles.

- Reliable Supply of Parts: Miller Toyota has a reliable supply of genuine Toyota parts, ensuring that customers can get their vehicles repaired quickly and efficiently.

- Expert Service and Maintenance: Miller Toyota’s technicians are trained by Toyota and have access to the latest diagnostic tools and equipment, ensuring that customers receive expert service and maintenance.

By choosing Miller Toyota, customers in Boise can be confident that they are getting the best possible Toyota experience. Visit millertoyota.net to explore the latest models, schedule a service appointment, or learn more about the dealership’s commitment to customer satisfaction.

10. What are Toyota’s Future Plans for Manufacturing?

Toyota has ambitious plans for the future of manufacturing, focusing on innovation, sustainability, and meeting the evolving needs of customers.

10.1. What are Toyota’s Investments in Electric Vehicle (EV) Manufacturing?

Toyota is investing heavily in electric vehicle (EV) manufacturing, with plans to introduce a range of new EVs in the coming years. The company is also developing advanced battery technology to improve the performance and range of its EVs. According to Toyota’s official website, they plan to expand their electric vehicle lineup to 30 models by 2030.

10.2. How is Toyota Incorporating Sustainability into its Manufacturing Processes?

Toyota is committed to incorporating sustainability into its manufacturing processes, with a focus on reducing waste, conserving energy, and minimizing its environmental impact. The company is implementing a variety of initiatives, including:

- Using Renewable Energy: Increasing the use of renewable energy sources, such as solar and wind power, in its manufacturing plants.

- Recycling and Reuse: Recycling and reusing materials whenever possible to reduce waste.

- Water Conservation: Implementing water conservation measures to reduce water consumption.

- Reducing Emissions: Reducing emissions from its manufacturing plants to minimize its environmental impact.

10.3. What Innovations is Toyota Implementing in its Manufacturing Facilities?

Toyota is implementing a variety of innovations in its manufacturing facilities to improve efficiency, quality, and safety. Some of these innovations include:

- Automation and Robotics: Using automation and robotics to streamline production processes and reduce human error.

- Artificial Intelligence (AI): Using artificial intelligence (AI) to optimize production schedules and improve quality control.

- 3D Printing: Using 3D printing to create prototypes and custom parts quickly and efficiently.

- Virtual Reality (VR): Using virtual reality (VR) to train employees and simulate manufacturing processes.

By embracing innovation and sustainability, Toyota is positioning itself for continued success in the automotive industry. Visit millertoyota.net to learn more about Toyota’s commitment to quality, innovation, and customer satisfaction.

Discover Your Ideal Toyota at Miller Toyota in Boise, Idaho

Are you in the market for a new or used Toyota in the Boise area? Do you need reliable service or genuine Toyota parts? Look no further than Miller Toyota.

Why Choose Miller Toyota?

- Wide Selection of Vehicles: Explore a wide selection of new and used Toyota models to find the perfect fit for your needs and budget.

- Expert Service and Maintenance: Trust our team of certified technicians to keep your Toyota running smoothly with expert service and maintenance.

- Genuine Toyota Parts: Ensure the quality and longevity of your vehicle with genuine Toyota parts.

- Convenient Financing Options: Take advantage of our convenient financing options to make your dream car a reality.

- Exceptional Customer Service: Experience exceptional customer service from our knowledgeable and friendly staff.

Take Action Today

- Visit our Website: Browse our inventory, schedule a service appointment, and explore our financing options at millertoyota.net.

- Call us: Speak with one of our friendly representatives at +1 (208) 376-8888 to learn more about our services and inventory.

- Visit our Dealership: Stop by our dealership at 208 N Maple Grove Rd, Boise, ID 83704, United States, and experience the Miller Toyota difference firsthand.

Miller Toyota is your trusted source for all things Toyota in Boise, Idaho. We are committed to providing you with the best possible car-buying and ownership experience. Contact us today and let us help you find your perfect Toyota.

FAQ: Who Manufactures Toyota?

1. Who actually manufactures Toyota vehicles?

Toyota Motor Corporation manufactures Toyota vehicles. It is a Japanese multinational automotive manufacturer headquartered in Toyota City, Japan.

2. Where are Toyota cars primarily manufactured?

Toyota cars are manufactured in various locations worldwide, including Japan, North America (United States, Canada, and Mexico), Europe, and Asia.

3. Does Toyota manufacture any vehicles in the USA?

Yes, Toyota manufactures several models in the USA, including the Camry, Corolla, Highlander, Tacoma, and Tundra.

4. Which company manufactures Toyota cars in the United States?

Toyota Motor Manufacturing, USA, Inc. is responsible for manufacturing Toyota cars in the United States. They have various manufacturing plants located in different states.

5. What specific Toyota models are made in Kentucky?

At the Toyota Motor Manufacturing Kentucky (TMMK) plant, the Camry, Camry Hybrid, and Avalon are produced.

6. Where can I find a reliable Toyota dealership in Boise, Idaho?

For a reliable Toyota dealership in Boise, Idaho, visit Miller Toyota at millertoyota.net. They offer a wide selection of new and used Toyota vehicles and expert service.

7. What does Toyota Motor Manufacturing Indiana (TMMI) specialize in?

Toyota Motor Manufacturing Indiana (TMMI) specializes in producing SUVs and minivans, including the Highlander, Sequoia, and Sienna.

8. How does Toyota ensure the quality of its manufactured vehicles?

Toyota ensures quality through the Toyota Production System (TPS), which emphasizes efficiency, continuous improvement, and respect for people, aiming to eliminate waste and improve quality at every stage.

9. What is Toyota Motor Manufacturing Texas (TMMTX) known for?

Toyota Motor Manufacturing Texas (TMMTX) is known for specializing in the production of full-size pickup trucks like the Tacoma and Tundra.

10. How does local manufacturing benefit Toyota customers in the USA?

Local manufacturing allows Toyota to respond quickly to market demands, reduce transportation costs, and offer competitive pricing, ensuring timely delivery of vehicles to dealerships like Miller Toyota and benefiting customers with access to the latest models and reliable parts supply.