Are you curious about where Toyota cars are manufactured? Toyota vehicles are assembled in various locations around the world, including North America, and millertoyota.net provides details. This guide explores Toyota’s manufacturing footprint, focusing on North American production, models built in the US, and the economic impact. Discover where your favorite Toyota is made and what it means for the American economy, all on millertoyota.net.

1. What Countries Manufacture Toyota Cars?

Toyota cars are manufactured in numerous countries worldwide, including Japan, the United States, Canada, Mexico, and several others across Asia, Europe, and South America. According to Toyota’s global manufacturing network, this widespread production ensures that Toyota can meet local market demands efficiently and contribute to economies around the globe.

Expanding on Toyota’s global reach, the company strategically locates its manufacturing plants to optimize production costs, reduce transportation expenses, and cater to regional preferences. For instance, plants in Asia often focus on producing compact and subcompact models popular in those markets, while North American facilities tend to concentrate on larger vehicles like trucks and SUVs. This localization strategy helps Toyota maintain competitiveness and responsiveness to diverse consumer needs. Toyota’s commitment to global manufacturing also supports local communities through job creation and economic development.

2. Where in the United States Are Toyota Cars Manufactured?

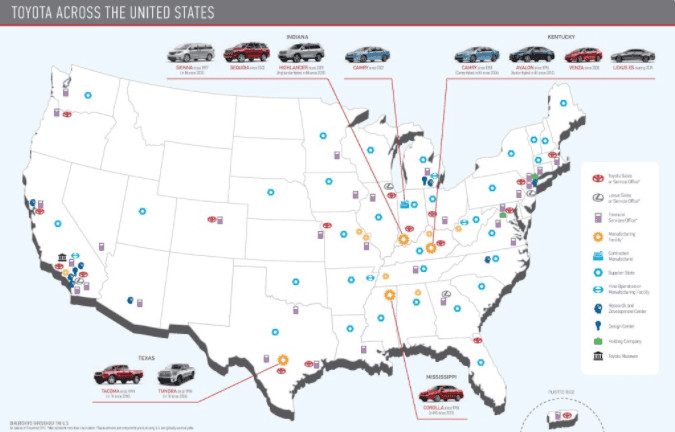

Toyota manufactures vehicles in several U.S. states, including Kentucky, Indiana, Mississippi, Texas, Alabama, and West Virginia. These facilities produce a wide range of models, from sedans and SUVs to trucks and engines, contributing significantly to the American automotive industry. Miller Toyota, serving the Boise area, understands the importance of this local production.

Toyota Manufacturing Plants in North America

Toyota Manufacturing Plants in North America

2.1. Toyota Motor Manufacturing Kentucky (TMMK)

Located in Georgetown, Kentucky, Toyota Motor Manufacturing Kentucky (TMMK) is Toyota’s largest manufacturing facility outside of Japan. Established in 1986, TMMK produces some of Toyota’s most popular models, including the Camry, Camry Hybrid, and Avalon. TMMK has a significant impact on the local economy, employing thousands of Kentuckians and contributing billions of dollars to the state’s GDP.

According to a 2023 economic impact study by the Kentucky Association of Manufacturers, TMMK supports over 80,000 direct and indirect jobs in Kentucky. The plant has also received numerous awards for its commitment to environmental sustainability and operational excellence. TMMK continuously invests in new technologies and processes to enhance its production capabilities and reduce its environmental footprint.

2.2. Toyota Motor Manufacturing Indiana (TMMI)

Situated in Princeton, Indiana, Toyota Motor Manufacturing Indiana (TMMI) focuses on producing SUVs and minivans. The plant’s current lineup includes the Highlander, Grand Highlander, and Sienna. Opened in 1996, TMMI has expanded its operations over the years to meet growing demand for Toyota’s popular family vehicles.

TMMI is known for its advanced manufacturing techniques and commitment to quality. The plant has implemented several innovative programs to improve efficiency and reduce waste. According to a 2022 report by the Indiana Economic Development Corporation, TMMI contributes over $4 billion annually to Indiana’s economy. The facility also partners with local educational institutions to provide training and development opportunities for its employees.

2.3. Toyota Motor Manufacturing Mississippi (TMMMS)

Located in Blue Springs, Mississippi, Toyota Motor Manufacturing Mississippi (TMMMS) primarily produces the Corolla. The plant began operations in 2011 and has since become a key manufacturing hub for Toyota’s compact vehicles. TMMMS is recognized for its modern facilities and efficient production processes.

TMMMS plays a vital role in Mississippi’s economy, providing jobs and supporting local businesses. The plant has invested significantly in community development initiatives, including education and workforce training programs. According to a 2023 study by the Mississippi Development Authority, TMMMS contributes over $1.5 billion annually to the state’s economy. The facility also focuses on sustainability, implementing various measures to reduce its environmental impact.

2.4. Toyota Motor Manufacturing Texas (TMMTX)

Based in San Antonio, Texas, Toyota Motor Manufacturing Texas (TMMTX) specializes in producing pickup trucks. The plant’s primary products are the Tundra and Tacoma. TMMTX was established in 2003 and has become a major contributor to the Texas economy.

TMMTX is known for its state-of-the-art manufacturing processes and commitment to quality. The plant has implemented several innovative programs to improve efficiency and reduce waste. According to a 2022 report by the Texas Comptroller of Public Accounts, TMMTX contributes over $3 billion annually to Texas’s economy. The facility also supports local communities through various philanthropic initiatives, including scholarships and community grants.

2.5. Mazda Toyota Manufacturing (MTM)

Located in Huntsville, Alabama, Mazda Toyota Manufacturing (MTM) is a joint venture between Toyota and Mazda. The plant produces the Toyota Corolla Cross. MTM began operations in 2021 and represents a significant investment in the region’s automotive industry.

MTM is committed to using advanced manufacturing technologies and sustainable practices. The plant has implemented several innovative programs to reduce its environmental footprint. According to a 2023 report by the Alabama Department of Commerce, MTM is expected to contribute over $5 billion to Alabama’s economy over the next decade. The facility also focuses on workforce development, providing training and apprenticeship opportunities for its employees.

2.6. Toyota Motor Manufacturing West Virginia (TMMWV)

Situated in Buffalo, West Virginia, Toyota Motor Manufacturing West Virginia (TMMWV) focuses on producing engines and transmissions. The plant supplies powertrain components for various Toyota models assembled in North America. TMMWV plays a crucial role in Toyota’s North American manufacturing operations.

TMMWV is known for its advanced manufacturing technologies and commitment to quality. The plant has implemented several innovative programs to improve efficiency and reduce waste. According to a 2022 report by the West Virginia Development Office, TMMWV contributes over $800 million annually to West Virginia’s economy. The facility also supports local communities through various philanthropic initiatives, including education and environmental conservation programs.

3. Which Toyota Models Are Made in the USA?

Several popular Toyota models are manufactured in the United States. This includes the Camry, Avalon, Highlander, Sequoia, Tundra, Tacoma, Corolla, and Corolla Cross. Manufacturing these models domestically supports American jobs and contributes to the U.S. economy. At millertoyota.net, you can explore the specifications and features of these American-made Toyota vehicles.

Here’s a quick overview:

| Model | Manufacturing Plant(s) |

|---|---|

| Camry | Toyota Motor Manufacturing Kentucky (TMMK) |

| Avalon | Toyota Motor Manufacturing Kentucky (TMMK) |

| Highlander | Toyota Motor Manufacturing Indiana (TMMI) |

| Grand Highlander | Toyota Motor Manufacturing Indiana (TMMI) |

| Sequoia | Toyota Motor Manufacturing Indiana (TMMI) |

| Tundra | Toyota Motor Manufacturing Texas (TMMTX) |

| Tacoma | Toyota Motor Manufacturing Texas (TMMTX) |

| Corolla | Toyota Motor Manufacturing Mississippi (TMMMS) |

| Corolla Cross | Mazda Toyota Manufacturing (MTM), Huntsville, Alabama |

4. How Does Toyota’s U.S. Manufacturing Benefit the American Economy?

Toyota’s U.S. manufacturing operations provide substantial benefits to the American economy, including job creation, economic investment, and support for local communities. These facilities employ tens of thousands of Americans and contribute billions of dollars to the U.S. GDP. Miller Toyota recognizes the importance of this economic impact.

4.1. Job Creation

Toyota’s manufacturing plants in the U.S. directly employ thousands of workers, providing stable jobs with competitive wages and benefits. These jobs range from production line workers and engineers to administrative staff and management positions. According to a 2023 report by the Center for Automotive Research, each direct job in automotive manufacturing supports approximately seven indirect jobs in related industries, such as suppliers, logistics, and services.

Toyota also invests in workforce development programs to train and upskill its employees. These programs help workers enhance their skills and advance their careers within the company. Toyota’s commitment to job creation and workforce development contributes to economic stability and growth in the communities where it operates.

4.2. Economic Investment

Toyota has invested billions of dollars in its U.S. manufacturing facilities, building state-of-the-art plants and equipping them with advanced technologies. These investments boost local economies by creating construction jobs, supporting suppliers, and generating tax revenue for state and local governments.

Toyota’s investments also drive innovation in manufacturing processes and technologies. The company continuously seeks ways to improve efficiency, reduce waste, and enhance product quality. These innovations benefit not only Toyota but also the broader U.S. manufacturing sector.

4.3. Support for Local Communities

Toyota actively supports the communities where it operates through philanthropic initiatives, community grants, and volunteer programs. The company invests in education, environmental conservation, and other programs that improve the quality of life for local residents.

Toyota also partners with local organizations to address community needs and promote economic development. For example, Toyota supports scholarships for students pursuing careers in STEM fields and provides grants to local schools and non-profit organizations. These efforts help strengthen communities and create opportunities for individuals to succeed.

4.4. Contribution to U.S. GDP

Toyota’s U.S. manufacturing operations contribute significantly to the U.S. Gross Domestic Product (GDP). The economic activity generated by Toyota’s plants, suppliers, and related industries supports billions of dollars in economic output each year.

According to a 2022 report by the Bureau of Economic Analysis, the automotive industry as a whole contributes approximately 3% to the U.S. GDP. Toyota is one of the largest automotive manufacturers in the U.S., and its economic contributions are substantial. Toyota’s commitment to U.S. manufacturing helps drive economic growth and prosperity for the nation as a whole.

5. What Are the Most Popular Toyota Models in the Boise Area?

In the Boise area, popular Toyota models include the Tacoma, known for its reliability and off-road capabilities, the RAV4, a versatile and fuel-efficient SUV, and the Tundra, a powerful and capable pickup truck. Miller Toyota offers a wide selection of these models to meet local customer preferences.

5.1. Toyota Tacoma

The Toyota Tacoma is a popular choice among Boise residents due to its ruggedness, reliability, and off-road capabilities. Boise’s proximity to outdoor recreation areas like the Boise National Forest makes the Tacoma an ideal vehicle for adventurers. The Tacoma is known for its strong resale value and durable construction, making it a smart investment for those who need a dependable truck.

Miller Toyota offers a variety of Tacoma configurations, including different cab styles, bed lengths, and trim levels. Customers can choose from models equipped with features like four-wheel drive, off-road suspension, and advanced safety technologies. The Tacoma’s versatility and capability make it a top pick for Boise drivers.

5.2. Toyota RAV4

The Toyota RAV4 is a versatile and fuel-efficient SUV that appeals to a wide range of Boise drivers. Its spacious interior, comfortable ride, and advanced safety features make it a great choice for families and commuters alike. The RAV4 is also available in hybrid and plug-in hybrid versions, offering even better fuel economy and reduced emissions.

Miller Toyota offers a wide selection of RAV4 models, including different trim levels and options packages. Customers can choose from models equipped with features like all-wheel drive, panoramic sunroof, and premium audio systems. The RAV4’s popularity in Boise reflects its ability to meet the diverse needs of local drivers.

5.3. Toyota Tundra

The Toyota Tundra is a powerful and capable pickup truck that is well-suited to the needs of Boise’s growing population. Its robust engine, spacious cabin, and advanced technology features make it a popular choice for those who need a truck for work or recreation. The Tundra is known for its reliability and durability, making it a smart investment for those who demand a dependable vehicle.

Miller Toyota offers a variety of Tundra configurations, including different cab styles, bed lengths, and trim levels. Customers can choose from models equipped with features like four-wheel drive, tow packages, and advanced safety technologies. The Tundra’s combination of power, capability, and reliability make it a top pick for Boise truck buyers.

6. How Does Toyota Ensure Quality Control in Its Manufacturing Plants?

Toyota maintains rigorous quality control standards in all its manufacturing plants, using the Toyota Production System (TPS) to ensure consistency and excellence. This system emphasizes continuous improvement, defect prevention, and employee involvement. Miller Toyota values the quality and reliability that result from these stringent standards.

6.1. The Toyota Production System (TPS)

The Toyota Production System (TPS) is a comprehensive management philosophy and set of practices that focuses on eliminating waste, improving efficiency, and ensuring quality in all aspects of manufacturing. TPS is based on two main pillars: Just-in-Time (JIT) and Jidoka.

Just-in-Time (JIT) is a production strategy that aims to produce goods only when they are needed, reducing inventory costs and minimizing waste. JIT requires close coordination between suppliers, manufacturers, and customers to ensure that materials and products are delivered on time and in the right quantities.

Jidoka is a quality control principle that empowers workers to stop the production line whenever they detect a defect or abnormality. This prevents defective products from moving further down the line and ensures that quality issues are addressed immediately. Jidoka also encourages workers to identify and solve the root causes of defects, leading to continuous improvement in product quality.

6.2. Continuous Improvement (Kaizen)

Continuous improvement, also known as Kaizen, is a key element of Toyota’s quality control process. Kaizen involves making small, incremental improvements to processes and products on an ongoing basis. Toyota encourages all employees to participate in Kaizen activities, fostering a culture of continuous learning and improvement.

Kaizen events are often organized to bring together cross-functional teams to identify and solve specific problems. These events typically involve brainstorming sessions, data analysis, and the implementation of solutions. The results of Kaizen activities are carefully monitored and evaluated to ensure that they are achieving the desired outcomes.

6.3. Defect Prevention

Toyota places a strong emphasis on preventing defects from occurring in the first place. This involves carefully designing products and processes to minimize the risk of errors. Toyota also uses advanced technologies, such as automated inspection systems and statistical process control, to monitor production processes and detect potential problems early on.

Toyota’s defect prevention efforts extend beyond its own manufacturing plants to its suppliers. Toyota works closely with its suppliers to ensure that they meet the company’s strict quality standards. Toyota also provides training and support to help suppliers improve their processes and prevent defects.

6.4. Employee Involvement

Toyota believes that its employees are its most valuable asset and that their involvement is essential to ensuring quality control. Toyota empowers its employees to take ownership of their work and to identify and solve problems. Toyota also provides its employees with extensive training and development opportunities to help them improve their skills and knowledge.

Toyota’s employee involvement efforts include suggestion programs, quality circles, and cross-functional teams. These initiatives encourage employees to share their ideas and work together to improve processes and products. Toyota also recognizes and rewards employees for their contributions to quality control.

7. How Can I Find a Toyota Made in the USA at Miller Toyota?

Finding a Toyota made in the USA at Miller Toyota is easy. Our sales team can help you identify the specific models and trim levels that are manufactured in the United States. You can also check the vehicle’s VIN (Vehicle Identification Number) to determine its country of origin. Visit millertoyota.net for our inventory and contact information.

7.1. Consult with Our Sales Team

The sales team at Miller Toyota is knowledgeable about the origin of the vehicles we sell and can assist you in finding a Toyota model that is manufactured in the USA. Our sales professionals can provide you with detailed information about the manufacturing locations of different Toyota models and trim levels.

When you visit Miller Toyota, be sure to let our sales team know that you are specifically interested in a Toyota model made in the USA. They can guide you to the vehicles that meet your criteria and answer any questions you may have about their origin.

7.2. Check the Vehicle Identification Number (VIN)

The Vehicle Identification Number (VIN) is a unique code assigned to every vehicle manufactured. The VIN contains information about the vehicle’s manufacturer, model, year, and assembly location. You can use the VIN to determine the country of origin of a Toyota vehicle.

The first character of the VIN indicates the country where the vehicle was manufactured. For example, a VIN that starts with “1,” “4,” or “5” indicates that the vehicle was manufactured in the United States. You can find the VIN on the vehicle’s dashboard, near the windshield, or on the driver’s side doorjamb.

7.3. Browse Our Online Inventory

Miller Toyota’s website, millertoyota.net, features an online inventory of all the new and used vehicles we have in stock. You can use the search filters on our website to narrow down your options and find Toyota models that are manufactured in the USA.

Our online inventory includes detailed information about each vehicle, including its VIN, features, and specifications. You can also view photos and videos of the vehicles to get a better sense of their appearance and condition.

7.4. Contact Us for More Information

If you have any questions about finding a Toyota made in the USA at Miller Toyota, please don’t hesitate to contact us. Our friendly and knowledgeable staff is available to answer your questions and provide you with the information you need.

You can reach us by phone, email, or by visiting our dealership in person. We are committed to providing excellent customer service and helping you find the perfect Toyota vehicle to meet your needs.

8. Are There Any Incentives for Buying a Car Made in the USA?

While there aren’t specific federal incentives solely for buying cars made in the USA, some state or local programs might offer incentives based on environmental factors or economic development goals. Always check with local authorities and dealerships like Miller Toyota for the latest information.

8.1. State and Local Incentives

Some state and local governments offer incentives to promote the purchase of vehicles that are manufactured locally or that meet certain environmental standards. These incentives may include tax credits, rebates, or other financial benefits.

For example, some states offer tax credits for purchasing electric vehicles or hybrid vehicles that are manufactured within the state. These incentives are designed to encourage consumers to support local manufacturers and reduce their carbon footprint.

8.2. Federal Tax Credits for Electric Vehicles

The federal government offers tax credits for the purchase of new electric vehicles (EVs) and plug-in hybrid vehicles (PHEVs). These tax credits can help offset the cost of purchasing an EV or PHEV and make them more accessible to consumers.

The amount of the tax credit varies depending on the vehicle’s battery capacity and other factors. Some EVs and PHEVs may be eligible for a tax credit of up to $7,500. To qualify for the tax credit, the vehicle must meet certain requirements, including being manufactured by a qualified manufacturer and having a battery capacity of at least 7 kilowatt-hours.

8.3. Check with Local Authorities and Dealerships

To find out about any incentives that may be available for buying a car made in the USA, it’s best to check with local authorities and dealerships like Miller Toyota. Our sales team can provide you with information about any state or local programs that may offer incentives for purchasing a Toyota vehicle that is manufactured in the USA.

You can also contact your state’s department of revenue or department of motor vehicles to inquire about any tax credits or rebates that may be available. Additionally, you can check with local environmental organizations or consumer advocacy groups to learn about any incentives that may be offered by non-governmental organizations.

9. What is Toyota’s Commitment to Sustainability in Manufacturing?

Toyota is committed to sustainability in its manufacturing processes, focusing on reducing emissions, conserving resources, and minimizing waste. These efforts align with global sustainability goals and enhance Toyota’s reputation as an environmentally responsible automaker. Miller Toyota supports Toyota’s commitment to sustainability.

9.1. Reducing Emissions

Toyota is committed to reducing greenhouse gas emissions from its manufacturing operations. The company has set ambitious targets for reducing its carbon footprint and is implementing a variety of measures to achieve these goals.

One of the key strategies Toyota is using to reduce emissions is improving energy efficiency in its manufacturing plants. This includes investing in energy-efficient equipment, optimizing production processes, and implementing energy management systems. Toyota is also using renewable energy sources, such as solar and wind power, to generate electricity for its manufacturing plants.

9.2. Conserving Resources

Toyota is committed to conserving natural resources in its manufacturing processes. The company is implementing a variety of measures to reduce its consumption of water, energy, and raw materials.

One of the key strategies Toyota is using to conserve resources is promoting recycling and reuse. Toyota recycles a wide range of materials, including metal, plastic, and paper. The company also reuses materials whenever possible, reducing the need to extract and process new resources.

9.3. Minimizing Waste

Toyota is committed to minimizing waste in its manufacturing operations. The company is implementing a variety of measures to reduce the amount of waste it generates and to ensure that any waste that is generated is disposed of responsibly.

One of the key strategies Toyota is using to minimize waste is promoting the 3Rs: Reduce, Reuse, and Recycle. Toyota encourages its employees to find ways to reduce the amount of waste they generate, to reuse materials whenever possible, and to recycle materials that cannot be reused.

9.4. Environmental Management Systems

Toyota has implemented environmental management systems in all of its manufacturing plants. These systems are designed to ensure that the company complies with all applicable environmental regulations and that it continuously improves its environmental performance.

Toyota’s environmental management systems are based on the ISO 14001 standard, which is an internationally recognized standard for environmental management. The company’s environmental management systems include procedures for identifying and managing environmental risks, setting environmental objectives and targets, and monitoring and measuring environmental performance.

10. How Does Toyota Support the Communities Where It Manufactures Cars?

Toyota supports the communities where it manufactures cars through various initiatives, including charitable donations, educational programs, and volunteer activities. These efforts demonstrate Toyota’s commitment to being a responsible corporate citizen and contributing to the well-being of its employees and neighbors. Miller Toyota is proud to be part of the Toyota community.

10.1. Charitable Donations

Toyota makes charitable donations to a variety of organizations that support education, community development, and environmental conservation. These donations help to improve the quality of life for residents in the communities where Toyota operates.

For example, Toyota has donated millions of dollars to support STEM education programs in schools and universities. These programs help to prepare students for careers in science, technology, engineering, and mathematics. Toyota has also donated to organizations that provide job training and placement services for unemployed and underemployed individuals.

10.2. Educational Programs

Toyota supports a variety of educational programs that help to improve the skills and knowledge of students and workers. These programs include scholarships, internships, and apprenticeships.

For example, Toyota offers scholarships to students pursuing degrees in automotive technology and engineering. These scholarships help to attract talented individuals to the automotive industry and to ensure that there is a skilled workforce to support Toyota’s manufacturing operations. Toyota also offers internships and apprenticeships to provide students and workers with hands-on experience in the automotive industry.

10.3. Volunteer Activities

Toyota encourages its employees to volunteer in their communities. The company provides its employees with paid time off to volunteer and organizes volunteer events throughout the year.

For example, Toyota employees have volunteered to build homes for low-income families, clean up parks and trails, and mentor students. These volunteer activities help to strengthen communities and to promote a sense of civic responsibility among Toyota employees.

10.4. Community Partnerships

Toyota partners with local organizations to address community needs and promote economic development. These partnerships help to ensure that Toyota is responsive to the needs of the communities where it operates and that it is contributing to their long-term success.

For example, Toyota has partnered with local hospitals to provide healthcare services to underserved populations. The company has also partnered with local businesses to create jobs and stimulate economic growth. These community partnerships help to strengthen communities and to create opportunities for individuals to succeed.

Ready to explore the Toyota lineup and discover your next vehicle? Visit millertoyota.net to browse our inventory, schedule a test drive, and learn more about our services. Whether you’re looking for a fuel-efficient sedan, a versatile SUV, or a powerful truck, Miller Toyota has the perfect vehicle for you. Contact us today and let us help you find your dream Toyota! Visit us at 208 N Maple Grove Rd, Boise, ID 83704, United States or call +1 (208) 376-8888.

Frequently Asked Questions (FAQ)

FAQ 1: Does Toyota manufacture all its cars in the USA?

No, Toyota does not manufacture all its cars in the USA; it has manufacturing plants in several countries, including Japan, Canada, and Mexico, in addition to its U.S. facilities. According to Toyota’s global manufacturing network, this diverse production base allows the company to efficiently meet global demand and tailor production to regional market needs. The U.S. plants focus on specific models like the Camry, Tundra, and Highlander, while other regions produce different models to optimize production and distribution costs.

FAQ 2: How can I tell if my Toyota was made in the USA?

You can tell if your Toyota was made in the USA by checking the Vehicle Identification Number (VIN). According to the NHTSA VIN system, if the VIN starts with “1,” “4,” or “5,” the vehicle was manufactured in the United States. You can find the VIN on the dashboard (driver’s side) or the driver’s side doorjamb.

FAQ 3: What are the benefits of buying a Toyota made in the USA?

Buying a Toyota made in the USA supports American jobs, reduces transportation costs, and contributes to the U.S. economy. According to a report by the Economic Policy Institute, domestic manufacturing has a multiplier effect, creating additional jobs in supplier industries and local communities. Supporting American-made products helps strengthen the national economy.

FAQ 4: Which Toyota SUVs are manufactured in the United States?

Several Toyota SUVs are manufactured in the United States, including the Highlander, Grand Highlander, and Sequoia, all produced at Toyota Motor Manufacturing Indiana (TMMI). According to Toyota’s official website, these SUVs are built with a focus on quality and reliability, reflecting Toyota’s commitment to American manufacturing. The RAV4 used to be manufactured in the US, but it is now mostly manufactured in Japan.

FAQ 5: Are Toyota Tacoma trucks made in the USA?

Yes, Toyota Tacoma trucks are made in the USA at Toyota Motor Manufacturing Texas (TMMTX) in San Antonio. According to Toyota’s press releases, TMMTX has been the primary manufacturing location for the Tacoma, contributing significantly to the local Texas economy and providing jobs for thousands of workers.

FAQ 6: What is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is a comprehensive manufacturing philosophy focused on eliminating waste, improving efficiency, and ensuring quality. According to Toyota’s official explanation of TPS, it emphasizes “Just-in-Time” production and “Jidoka” (automation with a human touch), which empowers workers to stop the production line if a defect is detected. TPS is a key factor in Toyota’s reputation for reliability and efficiency.

FAQ 7: How does Toyota ensure quality control in its U.S. plants?

Toyota ensures quality control in its U.S. plants through the Toyota Production System (TPS), which includes continuous improvement (Kaizen), defect prevention, and employee involvement. According to internal Toyota quality reports, these practices ensure high standards are maintained throughout the manufacturing process, from initial design to final assembly.

FAQ 8: Does Mazda Toyota Manufacturing (MTM) produce only Toyota vehicles?

No, Mazda Toyota Manufacturing (MTM) in Huntsville, Alabama, is a joint venture that produces both Toyota and Mazda vehicles. According to a joint press release from Toyota and Mazda, MTM produces the Toyota Corolla Cross and Mazda CX-50, demonstrating the collaborative effort between the two companies in North American manufacturing.

FAQ 9: What is Toyota’s approach to environmental sustainability in its manufacturing plants?

Toyota’s approach to environmental sustainability includes reducing emissions, conserving resources, and minimizing waste. According to Toyota’s sustainability reports, the company invests in energy-efficient technologies, promotes recycling, and implements environmental management systems (ISO 14001) in its manufacturing plants to reduce its environmental impact.

FAQ 10: How does Toyota contribute to the local communities where it manufactures cars?

Toyota contributes to local communities through charitable donations, educational programs, and volunteer activities. According to Toyota’s community involvement reports, the company supports local schools, provides scholarships, and partners with non-profit organizations to improve the quality of life in the areas where its manufacturing plants are located, fostering strong relationships with the communities it serves.