Opening the seat on a Toyota forklift is a crucial skill for operators and maintenance personnel, and millertoyota.net provides expertise in Toyota forklift access. This guide will provide comprehensive instructions and safety precautions to open the seat on a Toyota forklift, ensuring proper maintenance and inspections, with access to our service department for professional support. Optimize your equipment’s lifespan with regular maintenance procedures today.

1. Understanding the Importance of Accessing the Seat

Accessing the seat on a Toyota forklift is essential for several reasons:

- Battery Maintenance: The battery is often located beneath the seat, requiring access for regular checks and maintenance.

- Component Inspection: Various components, such as hydraulic systems and electrical connections, may be located under the seat.

- Operator Comfort: Adjusting the seat and accessing controls can improve operator comfort and productivity.

1.1. Why Regular Access is Crucial

Regular access to the seat area allows for timely identification of potential issues. Early detection and correction of problems can prevent costly repairs and extend the life of your forklift. Maintenance practices also ensure the forklift meets safety standards and operates efficiently.

1.2. Key Benefits of Proper Seat Access

- Improved Safety: Proper inspection and maintenance ensure all components are functioning correctly.

- Extended Lifespan: Regular maintenance prevents minor issues from becoming major problems.

- Optimal Performance: Ensures the forklift operates at peak efficiency.

2. Safety Precautions Before You Begin

Before attempting to open the seat on your Toyota forklift, follow these safety precautions to prevent injuries and equipment damage. Safety is always a top priority when dealing with heavy machinery.

2.1. Turning Off the Forklift

Always turn off the forklift completely before beginning any maintenance or inspection. Remove the key from the ignition to prevent accidental starts. Ensure the parking brake is engaged to prevent movement.

2.2. Wearing Proper Personal Protective Equipment (PPE)

Wear appropriate PPE, including safety gloves and eye protection. This will protect you from potential hazards like battery acid or sharp edges. Consider wearing sturdy work boots for added safety.

2.3. Ensuring a Clear and Safe Workspace

Make sure the area around the forklift is clear of obstructions and other personnel. A clean, well-lit workspace reduces the risk of accidents. Use caution tape or cones to create a safety zone if necessary.

3. Locating the Seat Release Mechanism

The seat release mechanism on a Toyota forklift can vary depending on the model. Generally, it is located at the front or side of the seat. Consult your forklift’s operator manual for the exact location.

3.1. Common Locations for the Release Mechanism

- Front of the Seat: Look for a lever or handle positioned at the front of the seat.

- Side of the Seat: Check for a knob or latch on either side of the seat.

- Under the Seat: In some models, the release may be located underneath the seat, requiring you to reach under and feel for it.

3.2. Identifying the Correct Mechanism

The release mechanism is typically labeled or marked with a symbol indicating its purpose. Familiarize yourself with the appearance and function of the release mechanism before attempting to open the seat. The operator’s manual often includes diagrams or illustrations to help you identify it.

3.3. Consulting the Operator’s Manual

The operator’s manual is your best resource for locating the seat release mechanism. It provides detailed instructions and diagrams specific to your forklift model. Keep the manual readily available for reference.

4. Step-by-Step Guide to Opening the Seat

Follow these detailed steps to safely and effectively open the seat on your Toyota forklift. Each step is designed to ensure you can access the components beneath the seat without causing damage.

4.1. Engaging the Release Mechanism

Once you have located the release mechanism, engage it according to the instructions in the operator’s manual. This may involve pulling a lever, turning a knob, or pressing a latch. Ensure the mechanism is fully engaged before proceeding.

4.2. Lifting or Tilting the Seat

After engaging the release, carefully lift or tilt the seat. Some models may require you to lift the seat straight up, while others may tilt forward or to the side. Use smooth, controlled movements to avoid damaging the seat or any underlying components.

4.3. Securing the Seat in the Open Position

Some forklifts have a locking mechanism to secure the seat in the open position. Engage this mechanism to prevent the seat from accidentally closing while you are working. If there is no locking mechanism, prop the seat open with a suitable support to ensure it remains stable.

Toyota Forklift Seat

Toyota Forklift Seat

5. Common Issues and Troubleshooting

Sometimes, opening the seat on a Toyota forklift can present challenges. Here are some common issues you may encounter and how to troubleshoot them.

5.1. Stuck or Stiff Release Mechanism

If the release mechanism is stuck or stiff, avoid forcing it. Apply a small amount of lubricant, such as WD-40, to the mechanism and try again. If it remains stuck, consult a qualified technician to avoid damaging the mechanism.

5.2. Seat Not Lifting or Tilting Properly

If the seat does not lift or tilt properly after engaging the release, check for any obstructions or binding. Ensure that all cables and hoses are clear and not interfering with the seat’s movement. If the problem persists, inspect the hinges and pivots for damage or corrosion.

5.3. Locking Mechanism Malfunctions

If the locking mechanism fails to engage or disengage, inspect it for damage or debris. Clean the mechanism and apply a small amount of lubricant. If the problem continues, the locking mechanism may need to be repaired or replaced.

6. Maintenance and Care Tips for the Seat and Release Mechanism

Proper maintenance and care can extend the life of your forklift seat and release mechanism. Here are some tips to keep them in good working condition.

6.1. Regular Cleaning

Clean the seat and release mechanism regularly to remove dirt, debris, and contaminants. Use a mild detergent and a soft cloth. Avoid using harsh chemicals or abrasive cleaners, which can damage the seat material and mechanism components.

6.2. Lubrication

Periodically lubricate the release mechanism with a suitable lubricant. This will keep it moving smoothly and prevent corrosion. Apply the lubricant sparingly to avoid attracting dirt and debris.

6.3. Inspection and Replacement of Worn Parts

Regularly inspect the seat and release mechanism for signs of wear or damage. Replace any worn or damaged parts promptly to prevent further problems. Pay close attention to hinges, pivots, and locking mechanisms.

7. Safety Protocols for Battery Access and Maintenance

Once the seat is open, it is crucial to follow strict safety protocols when accessing and maintaining the battery. Batteries contain hazardous materials and can pose a significant risk if not handled properly.

7.1. Proper Ventilation

Ensure the area is well-ventilated to prevent the buildup of hazardous fumes. Open doors and windows, or use a fan to circulate air. Avoid working in enclosed spaces where fumes can accumulate.

7.2. Avoiding Sparks and Open Flames

Keep sparks and open flames away from the battery to prevent explosions. Batteries can produce hydrogen gas, which is highly flammable. Do not smoke or use electronic devices near the battery.

7.3. Handling Battery Acid Safely

Battery acid is corrosive and can cause severe burns. Wear safety gloves and eye protection to prevent contact with skin and eyes. If acid spills, neutralize it with baking soda and rinse thoroughly with water.

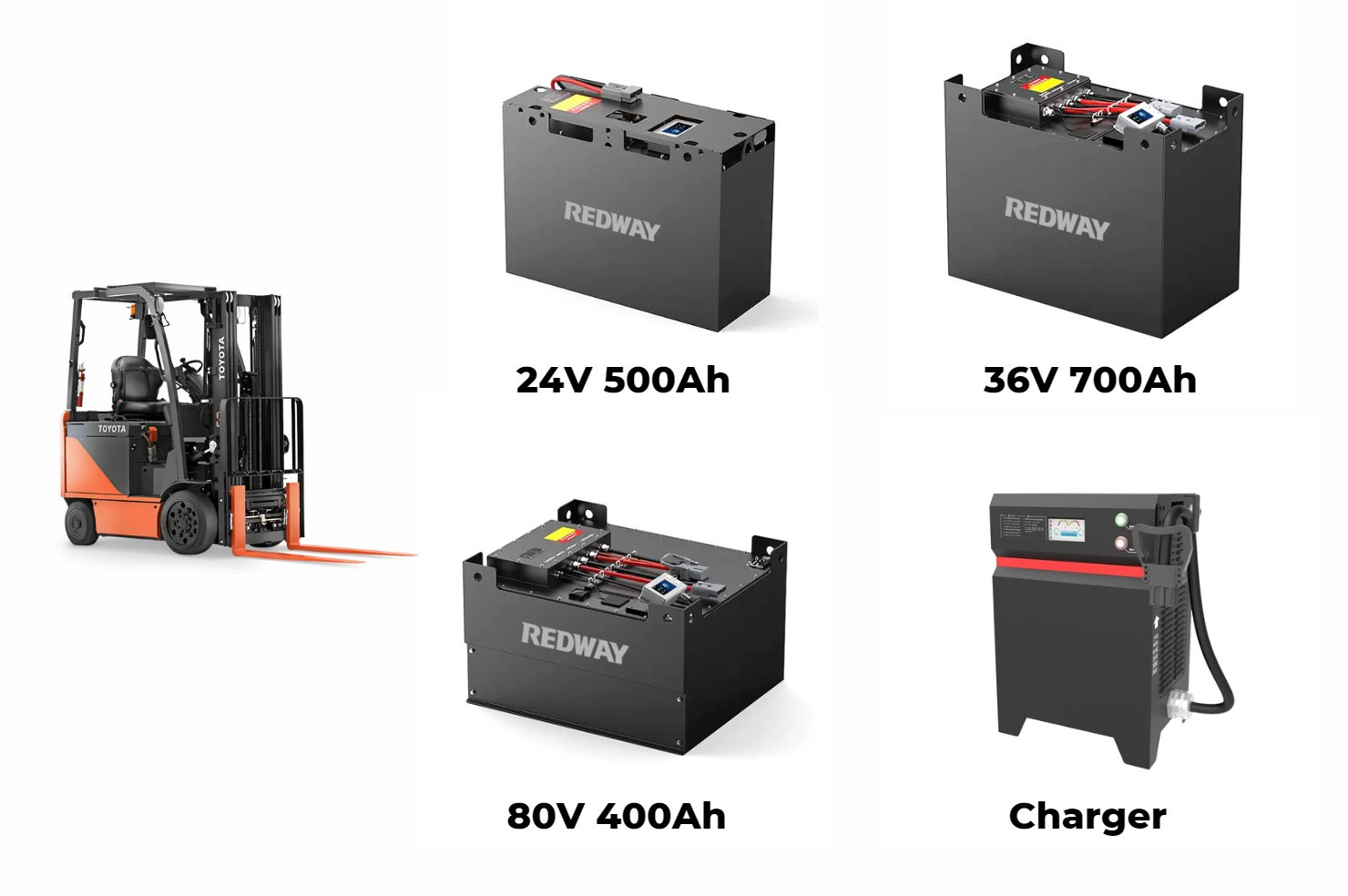

8. Understanding Battery Types in Toyota Forklifts

Toyota forklifts use various types of batteries, each with its own characteristics and maintenance requirements. Knowing the type of battery in your forklift is essential for proper care and handling.

8.1. Lead-Acid Batteries

Lead-acid batteries are the most common type used in forklifts. They are relatively inexpensive and provide reliable power. However, they require regular maintenance, including watering and cleaning.

8.2. Lithium-Ion Batteries

Lithium-ion batteries are becoming increasingly popular due to their high energy density, long lifespan, and low maintenance requirements. They are more expensive than lead-acid batteries but offer significant advantages in terms of performance and efficiency.

8.3. Nickel-Cadmium Batteries

Nickel-cadmium batteries are less common but offer good performance in extreme temperatures. They are more environmentally friendly than lead-acid batteries but have a lower energy density than lithium-ion batteries.

9. Step-by-Step Guide to Battery Inspection and Maintenance

Regular battery inspection and maintenance are crucial for ensuring the longevity and performance of your Toyota forklift. Follow these steps to keep your battery in good working condition.

9.1. Visual Inspection for Damage and Corrosion

Inspect the battery for any signs of damage, such as cracks, leaks, or swelling. Check the terminals and connections for corrosion. Clean any corrosion with a wire brush and a solution of baking soda and water.

9.2. Checking Electrolyte Levels (for Lead-Acid Batteries)

For lead-acid batteries, check the electrolyte levels regularly. The electrolyte should be above the plates in each cell. Add distilled water as needed to maintain the proper level.

9.3. Testing Battery Voltage

Use a voltmeter to test the battery voltage. A fully charged battery should read around 12.6 to 12.8 volts. If the voltage is significantly lower, the battery may need to be recharged or replaced.

10. Charging Procedures for Toyota Forklift Batteries

Proper charging is essential for maintaining the health and performance of your Toyota forklift battery. Follow these procedures to ensure safe and effective charging.

10.1. Selecting the Correct Charger

Use a charger that is specifically designed for the type of battery in your forklift. Using the wrong charger can damage the battery or reduce its lifespan. Consult your operator’s manual for recommended charger specifications.

10.2. Connecting the Charger

Connect the charger to the battery terminals, ensuring proper polarity. The positive (+) terminal on the charger should be connected to the positive (+) terminal on the battery, and the negative (-) terminal should be connected to the negative (-) terminal.

10.3. Monitoring the Charging Process

Monitor the charging process to ensure that the battery is charging correctly. Check the charger’s display for any error messages or warnings. Avoid overcharging the battery, as this can damage it.

11. Understanding the Electrical System Beneath the Seat

Beneath the seat of your Toyota forklift lies a complex electrical system that powers various components. Understanding this system is crucial for troubleshooting and maintenance.

11.1. Identifying Key Components

Key components of the electrical system include the battery, starter, alternator, wiring harness, and control modules. Familiarize yourself with the location and function of each component.

11.2. Common Electrical Issues

Common electrical issues include blown fuses, loose connections, and damaged wiring. Regular inspection and maintenance can help prevent these issues.

11.3. Troubleshooting Tips

When troubleshooting electrical issues, start by checking the fuses and connections. Use a multimeter to test for voltage and continuity. Consult the wiring diagram in your operator’s manual for assistance.

12. Hydraulic System Components and Maintenance

The hydraulic system is essential for lifting and lowering loads on your Toyota forklift. Proper maintenance of this system is crucial for safe and efficient operation.

12.1. Identifying Hydraulic Components

Key hydraulic components include the pump, reservoir, valves, cylinders, and hoses. Familiarize yourself with the location and function of each component.

12.2. Checking Fluid Levels

Check the hydraulic fluid level regularly. The fluid should be within the recommended range on the dipstick. Add hydraulic fluid as needed to maintain the proper level.

12.3. Inspecting for Leaks

Inspect the hydraulic system for leaks. Check the hoses, fittings, and cylinders for any signs of fluid leakage. Repair any leaks promptly to prevent loss of fluid and damage to the system.

13. Adjusting the Operator Seat for Comfort and Safety

Adjusting the operator seat is essential for ensuring comfort and safety while operating the forklift. A properly adjusted seat can reduce fatigue and improve productivity.

13.1. Adjusting Seat Height

Adjust the seat height so that your feet comfortably reach the pedals and your hands comfortably reach the steering wheel and controls.

13.2. Adjusting Seat Position

Adjust the seat position forward or backward so that you have a clear view of the load and your surroundings.

13.3. Adjusting Lumbar Support

Adjust the lumbar support to provide proper support for your lower back. This can help reduce fatigue and prevent back pain.

14. Utilizing millertoyota.net for Parts and Service Information

millertoyota.net is your go-to resource for parts and service information for your Toyota forklift. The website offers a wide range of resources to help you maintain and repair your equipment.

14.1. Accessing Parts Catalogs

Use millertoyota.net to access parts catalogs for your specific forklift model. This will help you identify the correct parts for your repairs.

14.2. Finding Service Manuals

Find service manuals on millertoyota.net to guide you through maintenance and repair procedures. These manuals provide detailed instructions and diagrams.

14.3. Scheduling Service Appointments

Schedule service appointments through millertoyota.net for professional maintenance and repairs. Our experienced technicians can help keep your forklift in top condition.

15. The Benefits of Choosing Miller Toyota for Your Forklift Needs

Choosing Miller Toyota for your forklift needs offers numerous benefits, including expert service, genuine parts, and a commitment to customer satisfaction.

15.1. Expert Service Technicians

Miller Toyota employs expert service technicians who are trained to work on Toyota forklifts. Our technicians have the knowledge and experience to diagnose and repair any issues with your equipment.

15.2. Genuine Toyota Parts

Miller Toyota uses genuine Toyota parts to ensure the highest quality and reliability. Genuine parts are designed to fit your forklift perfectly and provide optimal performance.

15.3. Commitment to Customer Satisfaction

Miller Toyota is committed to providing exceptional customer service. We strive to meet your needs and exceed your expectations.

16. Advanced Troubleshooting Techniques

For more complex issues, advanced troubleshooting techniques may be required. These techniques often involve specialized tools and knowledge.

16.1. Using Diagnostic Tools

Diagnostic tools can help identify and diagnose complex issues with your forklift. These tools can read error codes and provide detailed information about the system’s performance.

16.2. Electrical System Testing

Advanced electrical system testing involves using a multimeter and other specialized tools to test for voltage, continuity, and resistance.

16.3. Hydraulic System Testing

Advanced hydraulic system testing involves using pressure gauges and flow meters to measure the performance of the hydraulic pump, valves, and cylinders.

17. Preventive Maintenance Checklist for Toyota Forklifts

A preventive maintenance checklist can help you keep your Toyota forklift in good working condition and prevent costly repairs.

17.1. Daily Inspections

Perform daily inspections to check for any signs of damage or wear. Check fluid levels, tire pressure, and the operation of all controls.

17.2. Weekly Inspections

Perform weekly inspections to check the battery, electrical system, and hydraulic system. Lubricate any moving parts as needed.

17.3. Monthly Inspections

Perform monthly inspections to check the brakes, steering, and suspension. Replace any worn or damaged parts.

18. The Future of Forklift Battery Technology

The future of forklift battery technology is rapidly evolving, with new advancements promising improved performance, efficiency, and sustainability.

18.1. Solid-State Batteries

Solid-state batteries are a promising new technology that offers higher energy density, improved safety, and longer lifespan compared to traditional lithium-ion batteries.

18.2. Wireless Charging

Wireless charging is another emerging technology that could revolutionize the way forklifts are charged. Wireless charging systems allow you to charge your forklift without plugging it in, making the process more convenient and efficient.

18.3. Battery Management Systems (BMS)

Advanced BMS are being developed to optimize battery performance, extend lifespan, and improve safety. These systems monitor battery voltage, temperature, and current, and adjust charging and discharging parameters accordingly.

19. Safety Tips for Operating a Toyota Forklift

Operating a Toyota forklift safely is crucial for preventing accidents and injuries. Follow these safety tips to ensure a safe working environment.

19.1. Proper Training

Ensure that all operators are properly trained and certified to operate the forklift. Training should include instruction on safe operating procedures, load handling, and emergency procedures.

19.2. Load Handling

Always follow safe load handling procedures. Do not exceed the forklift’s rated capacity. Ensure that the load is properly secured and balanced.

19.3. Safe Operating Procedures

Follow safe operating procedures at all times. Drive at a safe speed, avoid sudden stops and starts, and be aware of your surroundings.

20. Conclusion: Maximizing Forklift Performance and Longevity

Maximizing forklift performance and longevity requires a combination of proper maintenance, safe operating procedures, and access to reliable parts and service. By following the tips and guidelines in this guide, you can keep your Toyota forklift in top condition and ensure safe and efficient operation. millertoyota.net is here to support you with expert service, genuine parts, and a commitment to customer satisfaction.

Optimize your equipment’s lifespan with regular maintenance procedures today! Contact us at Address: 208 N Maple Grove Rd, Boise, ID 83704, United States. Phone: +1 (208) 376-8888. Website: millertoyota.net for all your forklift needs.

FAQs

How do you get to the battery on a forklift?

To access the battery on a forklift, first ensure the forklift is powered off and safely parked. Remove any covers or panels securing the battery compartment, which may involve unscrewing bolts or releasing latches. Carefully lift out the battery or slide it out of the compartment, depending on the forklift model. Consult your operator’s manual for specific instructions related to your forklift model.

How to jump start a Toyota forklift?

To jump start a Toyota forklift, park a functioning vehicle nearby and connect jumper cables. Attach the positive (+) cable to the positive terminal of the forklift battery and the other end to the positive terminal of the donor battery. Connect the negative (-) cable to the negative terminal of the donor battery, then attach the other end to a metal ground on the forklift. Start the donor vehicle and let it charge the forklift battery for a few minutes before attempting to start the forklift.

How to check the battery of a forklift?

To check a forklift battery, first ensure it’s disconnected. Use a multimeter to measure the voltage across the battery terminals. A fully charged battery typically shows around 12.6 to 12.8 volts for lead-acid types. Inspect for any signs of corrosion, leaks, or swelling, and check the fluid levels if applicable. Regular inspections can prevent unexpected failures and prolong battery life.

How do you move a forklift with a dead battery?

To move a forklift with a dead battery, you can manually push it if it’s a smaller model, ensuring the parking brake is released. For larger models, use a tow truck or forklift towing equipment, adhering to the manufacturer’s guidelines for safe towing. Always consult the operator’s manual for specific instructions related to your forklift model.

What type of battery is best for a Toyota forklift?

The best type of battery for a Toyota forklift depends on your specific needs and operating conditions. Lead-acid batteries are a common and cost-effective option, while lithium-ion batteries offer longer life and faster charging times. Consult with Miller Toyota’s service experts to determine the best battery for your forklift model and usage.

How often should I charge my Toyota forklift battery?

You should charge your Toyota forklift battery when it drops to about 20% capacity, ensuring it’s done in a well-ventilated area. Avoid running it below 20% capacity to prolong battery life. Allowing time for cooling after charging is also important.

What are common signs of a failing forklift battery?

Common signs of a failing forklift battery include reduced lifting power, longer charging times, swelling or leakage from the battery case, and unusual smells or sounds during operation. Regular inspections can help identify these issues early. Contact Miller Toyota for a battery diagnostic check if you notice any of these signs.

How to dispose of forklift batteries safely?

Dispose of forklift batteries by following local regulations for hazardous waste. Contact a certified recycling facility that specializes in battery disposal. Never throw batteries in regular trash; ensure they are stored safely until they can be properly recycled or disposed of. Miller Toyota can also provide guidance on proper battery disposal methods.

Can I use any charger for my Toyota forklift battery?

No, you should only use a charger that is specifically designed for the type of battery in your forklift. Using the wrong charger can damage the battery or reduce its lifespan. Consult your operator’s manual for recommended charger specifications or contact Miller Toyota for assistance.

What maintenance is required for a Toyota forklift battery?

Maintenance for a Toyota forklift battery includes regularly checking electrolyte levels (for lead-acid batteries), cleaning terminals and connections, inspecting for damage or corrosion, and ensuring proper charging procedures. Regular maintenance can significantly enhance performance and extend lifespan.