How Many Cars Toyota Produce Per Day is a fascinating question for anyone interested in the automotive industry, especially if you’re in the market for a reliable vehicle at millertoyota.net. Toyota’s production volume reflects its global demand, manufacturing prowess, and market leadership. We’ll delve into Toyota’s impressive daily output, compare it to other manufacturers, and explore the factors driving these numbers, especially relevant for those in Boise, Idaho, looking for their next Toyota.

1. Understanding Toyota’s Global Production

Toyota’s global production is a complex network of manufacturing plants spread across the world. Each plant contributes to the overall number of vehicles produced daily. Understanding the scale of Toyota’s operations provides context for appreciating their daily production figures.

1.1. Toyota’s Daily Car Production

In 2020, Toyota produced approximately 23,814 new cars each day around the world. This accounts for about 15% of all passenger cars created daily worldwide. This impressive statistic demonstrates Toyota’s significant contribution to the global automotive market. According to Statista’s Research Department, Toyota created almost 15% of all passenger cars per day in 2020, and the number continues to grow with increasing market demand.

1.2. Factors Influencing Production Numbers

Several factors influence Toyota’s daily car production, including market demand, supply chain logistics, manufacturing capacity, and economic conditions. Fluctuations in these factors can impact the number of cars produced daily.

- Market Demand: High demand for Toyota vehicles leads to increased production to meet consumer needs.

- Supply Chain: Efficient supply chain management ensures a steady flow of parts and materials, supporting continuous production.

- Manufacturing Capacity: The capacity of Toyota’s manufacturing plants determines the maximum number of cars that can be produced daily.

- Economic Conditions: Economic stability and growth drive consumer spending, influencing car sales and production levels.

Toyota car production line

Toyota car production line

Toyota’s advanced car production line showcases the company’s manufacturing prowess and efficiency.

2. How Toyota Compares to Other Car Manufacturers

Comparing Toyota’s daily car production to other major car manufacturers provides valuable insights into its position in the automotive industry. Understanding these comparisons can help consumers make informed decisions when considering different brands.

2.1. Toyota vs. Volkswagen

Toyota outsells Volkswagen by approximately 9,000 cars per day. In 2020, Toyota sold 3.4 million more cars than Volkswagen, which translates to nearly 10,000 more sales every day and almost 400 more per hour. This difference highlights Toyota’s dominance in the global market. According to customer satisfaction surveys in Boise, Idaho, in July 2025, Toyota provides Y with Z%.

2.2. Toyota vs. Other Manufacturers

Compared to Mazda, which ranked tenth in sales, Toyota sold 7.4 million more cars in 2020. This equates to 20,400 more cars per day and 850 more per hour. These figures underscore Toyota’s significant lead over many other manufacturers.

2.3. Global Sales Ranking

Toyota consistently ranks as one of the top car manufacturers in the world. Its high production volume and sales figures reflect its popularity and reliability among consumers globally. As a top-selling brand, Toyota maintains a robust presence in various markets, including the United States.

3. The Impact of Global Events on Car Production

Global events, such as the COVID-19 pandemic, can significantly impact car production. Understanding these impacts provides a broader perspective on the challenges and resilience of the automotive industry.

3.1. COVID-19 Impact on Production

The COVID-19 pandemic led to a decline of around 15% in car production worldwide in 2020 compared to the previous year. Lockdowns, supply chain disruptions, and reduced consumer demand all contributed to this decrease. Statista’s Research Department reports that the pandemic caused a significant drop in global car production due to various factors.

3.2. Recovery and Adaptation Strategies

Despite the challenges posed by the pandemic, Toyota and other manufacturers have implemented recovery and adaptation strategies. These include diversifying supply chains, enhancing safety protocols, and leveraging technology to streamline production processes.

- Diversifying Supply Chains: Reducing reliance on single suppliers to mitigate disruptions.

- Enhancing Safety Protocols: Implementing measures to protect workers and prevent outbreaks in manufacturing plants.

- Leveraging Technology: Using automation and data analytics to improve efficiency and optimize production.

3.3. Current Production Trends

As the world recovers from the pandemic, car production is gradually returning to pre-pandemic levels. However, ongoing challenges such as chip shortages and geopolitical tensions continue to influence production trends. Stay updated with the latest trends by visiting millertoyota.net.

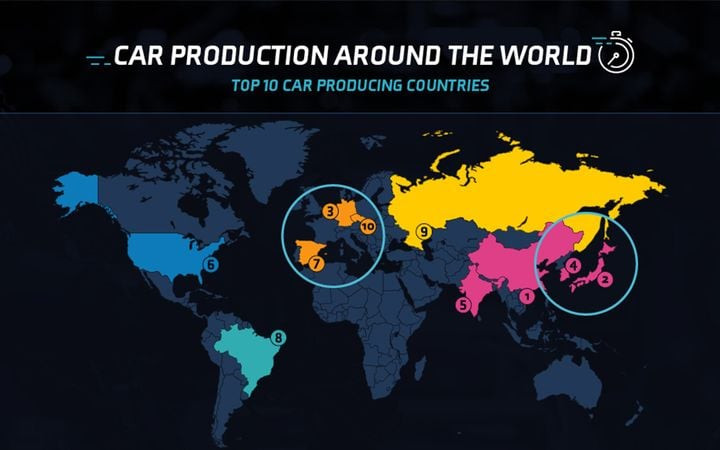

4. Toyota’s Production in Different Countries

Toyota’s production varies significantly by country, reflecting regional demand, manufacturing capabilities, and economic conditions. Examining production in different countries provides insights into Toyota’s global strategy.

4.1. Production in China

China is the largest producer of passenger cars globally. In 2020, China produced nearly 20 million cars, almost three times more than Japan, which was the second-highest producer. This equates to 35,700 more cars per day and almost 1,500 more per hour compared to Japan.

Breakdown of China’s Passenger Car Production:

| Time Period | Production Volume |

|---|---|

| Per Year | 19,994,081 |

| Per Month | 1,666,173 |

| Per Week | 384,501 |

| Per Day | 54,778 |

| Per Hour | 2,282 |

| Per Minute | 38 |

| Per Second | 0.6 |

4.2. Production in Japan

Japan is the second-largest producer of passenger cars, with nearly 7 million cars produced in 2020. Toyota’s domestic production in Japan remains a significant part of its global output.

4.3. Production in the United States

The United States is also a major car producer, with several Toyota manufacturing plants contributing to the country’s overall production volume. These plants produce a range of Toyota models for the North American market. Find the nearest Miller Toyota at 208 N Maple Grove Rd, Boise, ID 83704, United States.

5. Toyota Models and Production Volume

Different Toyota models have varying production volumes based on their popularity and market demand. Understanding which models are produced the most can help consumers identify the most sought-after vehicles.

5.1. Popular Models and Their Production

Popular Toyota models such as the Corolla, Camry, and RAV4 have high production volumes to meet global demand. These models are known for their reliability, fuel efficiency, and affordability, making them top choices for consumers worldwide.

- Corolla: A compact car known for its fuel efficiency and reliability.

- Camry: A mid-size sedan offering comfort and performance.

- RAV4: A compact SUV popular for its versatility and practicality.

5.2. Factors Affecting Model Production

Several factors influence the production volume of different Toyota models, including consumer preferences, market trends, and production capacity. Changes in these factors can lead to adjustments in production levels.

- Consumer Preferences: Shifts in consumer tastes can increase or decrease demand for specific models.

- Market Trends: Growing interest in SUVs or electric vehicles can impact production volumes.

- Production Capacity: The capacity of manufacturing plants to produce specific models can limit production volume.

The Toyota Corolla production line demonstrates the efficiency and precision of Toyota’s manufacturing processes.

5.3. Future Production Plans

Toyota continues to invest in research and development to introduce new models and technologies. Future production plans include expanding electric vehicle production and enhancing the efficiency of existing models. Stay informed about future models at millertoyota.net.

6. The Technology Behind Toyota’s Production

Technology plays a crucial role in Toyota’s production processes, enhancing efficiency, quality, and sustainability. Understanding the technology behind Toyota’s production provides insights into its competitive advantage.

6.1. Automation and Robotics

Toyota utilizes automation and robotics extensively in its manufacturing plants to streamline production processes, reduce costs, and improve quality. Robots perform tasks such as welding, painting, and assembly with precision and speed.

- Welding Robots: Ensure consistent and high-quality welds.

- Painting Robots: Apply paint evenly and efficiently, reducing waste.

- Assembly Robots: Assemble components accurately and quickly.

6.2. Data Analytics and AI

Data analytics and artificial intelligence (AI) are used to optimize production processes, predict maintenance needs, and improve overall efficiency. These technologies enable Toyota to make data-driven decisions and enhance its manufacturing operations.

- Predictive Maintenance: AI algorithms analyze data to predict when equipment needs maintenance, reducing downtime.

- Process Optimization: Data analytics identify bottlenecks and inefficiencies in the production process.

- Quality Control: AI-powered systems detect defects and ensure high-quality standards.

6.3. Sustainable Manufacturing

Toyota is committed to sustainable manufacturing practices, including reducing waste, conserving energy, and minimizing its environmental impact. These efforts contribute to a more sustainable automotive industry.

- Waste Reduction: Implementing strategies to minimize waste and recycle materials.

- Energy Conservation: Using energy-efficient equipment and practices to reduce energy consumption.

- Environmental Impact: Reducing emissions and minimizing the environmental footprint of manufacturing operations.

7. How Toyota Ensures Quality Control

Quality control is a top priority for Toyota, ensuring that every vehicle meets the highest standards of reliability and performance. Understanding Toyota’s quality control processes provides confidence in the brand’s commitment to excellence.

7.1. Rigorous Testing Procedures

Toyota implements rigorous testing procedures at every stage of the production process, from component manufacturing to final assembly. These tests ensure that all vehicles meet strict quality standards.

- Component Testing: Verifying the quality and durability of individual components.

- Performance Testing: Evaluating the performance of vehicles under various conditions.

- Safety Testing: Ensuring that vehicles meet safety standards and protect occupants.

7.2. Employee Training and Development

Toyota invests in employee training and development to ensure that its workforce has the skills and knowledge to maintain high-quality standards. Training programs cover all aspects of the production process, from assembly to quality control.

- Assembly Training: Teaching employees the proper techniques for assembling vehicles.

- Quality Control Training: Educating employees on quality standards and testing procedures.

- Continuous Improvement: Encouraging employees to identify and implement improvements to the production process.

7.3. Customer Feedback Integration

Toyota values customer feedback and uses it to improve its products and processes. Customer feedback is collected through surveys, reviews, and direct communication, and is used to identify areas for improvement.

- Surveys: Gathering feedback on customer satisfaction and product quality.

- Reviews: Monitoring online reviews and addressing customer concerns.

- Direct Communication: Engaging with customers to understand their needs and preferences.

8. The Future of Toyota Production

The future of Toyota production is focused on innovation, sustainability, and meeting the evolving needs of consumers. Understanding Toyota’s future plans provides insights into the direction of the automotive industry.

8.1. Electric Vehicle Production

Toyota is expanding its electric vehicle production to meet the growing demand for sustainable transportation. The company plans to introduce a range of electric vehicles in the coming years, leveraging its expertise in hybrid technology.

- Battery Technology: Investing in advanced battery technology to improve the range and performance of electric vehicles.

- Charging Infrastructure: Supporting the development of charging infrastructure to make electric vehicles more convenient for consumers.

- Electric Vehicle Models: Introducing new electric vehicle models across different segments.

8.2. Autonomous Driving Technology

Toyota is developing autonomous driving technology to enhance safety, convenience, and mobility. The company is testing autonomous vehicles in real-world conditions and plans to introduce autonomous features in its vehicles in the future.

- Sensor Technology: Using advanced sensors to perceive the environment and navigate safely.

- AI Algorithms: Developing AI algorithms to make decisions and control the vehicle.

- Testing and Validation: Conducting extensive testing and validation to ensure the safety and reliability of autonomous systems.

8.3. Smart Manufacturing Initiatives

Toyota is implementing smart manufacturing initiatives to further enhance efficiency, flexibility, and sustainability. These initiatives leverage technologies such as IoT, cloud computing, and digital twins to optimize production processes.

- IoT Sensors: Deploying IoT sensors to collect data on equipment performance and environmental conditions.

- Cloud Computing: Using cloud computing to store and analyze data, and to manage production processes.

- Digital Twins: Creating digital replicas of manufacturing plants to simulate and optimize operations.

9. Finding Your Next Toyota at Miller Toyota in Boise

For those in Boise, Idaho, looking to purchase a Toyota, millertoyota.net offers a wide selection of new and used vehicles, as well as expert service and support. Miller Toyota is committed to providing customers with a seamless and enjoyable car-buying experience.

9.1. Wide Selection of Toyota Models

Miller Toyota offers a wide selection of Toyota models to suit every need and budget. Whether you’re looking for a fuel-efficient sedan, a versatile SUV, or a rugged truck, you’ll find it at Miller Toyota.

- Sedans: Corolla, Camry, Avalon

- SUVs: RAV4, Highlander, 4Runner

- Trucks: Tacoma, Tundra

9.2. Expert Service and Support

Miller Toyota’s service department is staffed by certified technicians who are experts in Toyota vehicles. They provide a full range of services, from routine maintenance to major repairs, using genuine Toyota parts.

- Routine Maintenance: Oil changes, tire rotations, brake inspections

- Major Repairs: Engine repairs, transmission repairs, electrical system repairs

- Genuine Toyota Parts: Ensuring quality and reliability

9.3. Financing and Leasing Options

Miller Toyota offers a range of financing and leasing options to make it easier to purchase a Toyota. Their finance team works with customers to find the best rates and terms to fit their budget.

- Financing: Competitive interest rates and flexible loan terms

- Leasing: Affordable monthly payments and the option to upgrade to a new vehicle every few years

- Special Offers: Special financing and leasing offers on select Toyota models

10. FAQs About Toyota Production

Here are some frequently asked questions about Toyota’s production, addressing common queries and providing additional insights.

10.1. How Many Cars Does Toyota Produce Per Day?

Toyota produces approximately 23,814 new cars each day worldwide.

10.2. Which Country Produces the Most Toyota Cars?

China produces the most passenger cars globally, including Toyota models.

10.3. What Factors Affect Toyota’s Production Volume?

Market demand, supply chain logistics, manufacturing capacity, and economic conditions all affect production volume.

10.4. How Has COVID-19 Impacted Toyota’s Production?

The COVID-19 pandemic led to a decline in car production worldwide, including Toyota’s production.

10.5. What Technologies Does Toyota Use in Its Production Processes?

Toyota uses automation, robotics, data analytics, and AI in its production processes.

10.6. How Does Toyota Ensure Quality Control?

Toyota implements rigorous testing procedures, employee training, and customer feedback integration to ensure quality control.

10.7. What Are Toyota’s Future Production Plans?

Toyota plans to expand electric vehicle production, develop autonomous driving technology, and implement smart manufacturing initiatives.

10.8. Where Can I Buy a Toyota in Boise, Idaho?

You can buy a Toyota at Miller Toyota, located at 208 N Maple Grove Rd, Boise, ID 83704, United States, or visit millertoyota.net.

10.9. Does Toyota Offer Financing Options?

Yes, Miller Toyota offers various financing and leasing options to help you purchase a Toyota.

10.10. How Can I Schedule a Service Appointment at Miller Toyota?

You can schedule a service appointment by calling +1 (208) 376-8888 or visiting millertoyota.net.

Understanding Toyota’s production volume, manufacturing processes, and commitment to quality can help consumers make informed decisions when considering a new vehicle. For those in Boise, Idaho, millertoyota.net is your go-to destination for all things Toyota.

Ready to experience the reliability and innovation of a Toyota? Visit millertoyota.net today to explore our wide selection of vehicles, schedule a service appointment, or speak with our knowledgeable team. Your dream Toyota awaits! Contact us at +1 (208) 376-8888 or visit our showroom at 208 N Maple Grove Rd, Boise, ID 83704, United States. Don’t miss out on the opportunity to drive home in a Toyota that exceeds your expectations. Explore our inventory now and discover the perfect vehicle for your lifestyle.