How Many Cars Does Toyota Produce A Day? Toyota, available at millertoyota.net, stands out as a global leader in automotive manufacturing, known for reliability and innovation. This article explores Toyota’s impressive production capabilities, market dominance, and commitment to quality, with a local focus on how Miller Toyota in Boise meets the needs of its customers. Explore our wide selection of vehicles, service options, and financing solutions by visiting our site.

1. Understanding Toyota’s Global Production Scale

How many cars does Toyota make a day? Toyota produces approximately 24,000 cars per day worldwide, making them the leading car manufacturer in terms of daily output. This number reflects their vast global presence, efficient manufacturing processes, and strong market demand.

1.1. Toyota’s Worldwide Sales Performance

Toyota’s sales figures are a testament to its global appeal. In 2020, despite the challenges posed by the COVID-19 pandemic, Toyota sold over 8.5 million cars, surpassing all other manufacturers. This robust sales performance translates to nearly 24,000 cars sold each day. This dominance in sales is supported by Toyota’s reputation for reliability, fuel efficiency, and overall value.

Toyota Global Sales

Toyota Global Sales

1.2. Comparing Toyota to Other Manufacturers

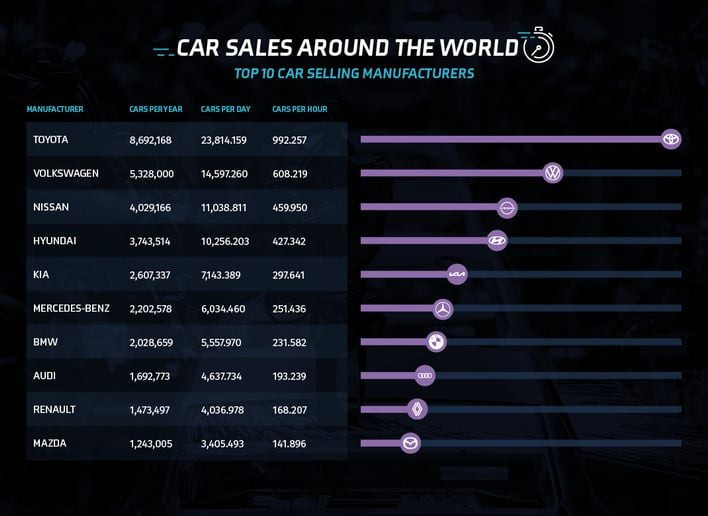

Compared to its competitors, Toyota’s production volume is notably higher. For instance, Toyota outsold Volkswagen by 3.4 million cars in 2020, which translates to approximately 10,000 more sales per day. This significant difference highlights Toyota’s operational efficiency and market reach. Toyota’s ability to consistently outperform its rivals underscores its commitment to quality and customer satisfaction, making it a preferred choice for car buyers globally.

1.3. Regional Production Variations

While Toyota’s global production averages around 24,000 cars per day, this number varies by region due to factors such as local demand, manufacturing capacity, and economic conditions. For example, production in Asia, particularly in China and Japan, tends to be higher due to the large consumer base and well-established manufacturing infrastructure.

1.4. Production Statistics Breakdown

Here’s a detailed breakdown of Toyota’s estimated production rate:

| Time Frame | Number of Cars |

|---|---|

| Per Year | 8.5 million |

| Per Day | 24,000 |

| Per Hour | 1,000 |

| Per Minute | 17 |

These figures highlight the scale of Toyota’s operations, illustrating its ability to consistently produce a large volume of vehicles to meet global demand.

1.5. Impact of COVID-19 on Production

The COVID-19 pandemic significantly impacted global automotive production. In 2020, overall passenger car production decreased by approximately 15% compared to the previous year. However, Toyota’s strong market position and efficient supply chain management allowed it to mitigate some of the adverse effects, maintaining a relatively high production volume compared to other manufacturers.

2. Factors Influencing Toyota’s Production Volume

What factors affect Toyota’s daily car production? Several factors influence Toyota’s daily car production, including technological advancements, supply chain efficiencies, market demand, and economic conditions.

2.1. Technological Advancements in Manufacturing

Toyota has long been at the forefront of automotive manufacturing technology. The Toyota Production System (TPS), renowned for its efficiency and waste reduction, plays a crucial role in maximizing output. Automation, robotics, and data analytics further enhance production speed and quality. These technological advancements enable Toyota to produce more cars per day with fewer resources and higher precision.

2.2. Supply Chain Efficiency

A robust and well-managed supply chain is essential for maintaining high production volumes. Toyota’s ability to source components efficiently and manage logistics effectively ensures that production lines keep moving. This involves strategic partnerships with suppliers and continuous monitoring of the supply chain to prevent disruptions. According to a study by the Harvard Business Review, Toyota’s supply chain practices are among the most efficient in the industry.

2.3. Market Demand and Consumer Preferences

Market demand significantly drives Toyota’s production volume. Consumer preferences for specific models, such as the RAV4, Camry, and Corolla, influence production planning. Toyota closely monitors market trends to adjust production accordingly, ensuring that popular models are readily available to meet customer demand. In areas like Boise, Idaho, where the demand for reliable and fuel-efficient vehicles is high, Toyota’s production is often geared towards these popular models.

2.4. Economic Conditions and Global Events

Economic conditions and global events, such as recessions, trade wars, and pandemics, can significantly impact automotive production. Economic downturns may reduce consumer spending, leading to lower demand and production cuts. Conversely, favorable economic conditions can boost demand and increase production. Toyota’s ability to adapt to these fluctuations is crucial for maintaining stable production levels.

2.5. Labor Force and Operational Capacity

Toyota’s skilled labor force and operational capacity are critical to its production output. The company invests heavily in training its employees and maintaining state-of-the-art manufacturing facilities. Ensuring that factories are running at optimal capacity and that workers are highly trained allows Toyota to maximize its daily car production.

3. Toyota’s Production System: The Key to Efficiency

What is the Toyota Production System (TPS) and how does it impact production? The Toyota Production System (TPS) is a management philosophy focused on minimizing waste and maximizing efficiency, impacting production by streamlining processes and improving quality.

3.1. Core Principles of TPS

The Toyota Production System (TPS) is built on two main pillars: continuous improvement (Kaizen) and respect for people. These principles drive the entire production process, encouraging employees to identify and eliminate waste, improve workflows, and enhance quality. TPS aims to achieve the highest possible efficiency by involving every member of the organization in the improvement process.

3.2. Waste Reduction (Muda)

A central tenet of TPS is the elimination of waste, known as “Muda.” Toyota identifies seven types of waste:

- Transportation: Minimizing unnecessary movement of materials.

- Inventory: Reducing excess inventory.

- Motion: Eliminating unnecessary movement of workers.

- Waiting: Reducing idle time.

- Overproduction: Avoiding producing more than needed.

- Over-processing: Reducing unnecessary steps in the production process.

- Defects: Minimizing errors and rework.

By systematically addressing these wastes, Toyota streamlines its production process, leading to higher output and lower costs.

3.3. Just-In-Time (JIT) Manufacturing

Just-In-Time (JIT) manufacturing is a key component of TPS, ensuring that materials and components arrive exactly when needed in the production process. This minimizes inventory costs and reduces the risk of obsolescence. JIT requires close coordination with suppliers and precise scheduling to ensure a smooth flow of materials.

3.4. Continuous Improvement (Kaizen)

Kaizen, or continuous improvement, is an ongoing effort to improve processes and eliminate waste. Toyota encourages all employees to identify areas for improvement and implement changes. This continuous feedback loop helps the company adapt to changing market conditions and improve overall efficiency.

3.5. Impact on Production Volume

The TPS has a profound impact on Toyota’s production volume. By eliminating waste, streamlining processes, and continuously improving, Toyota can produce more cars per day with the same resources. The system’s focus on efficiency and quality ensures that each vehicle meets high standards, enhancing Toyota’s reputation and driving sales.

4. The Role of Manufacturing Plants in Toyota’s Output

Where are Toyota’s major manufacturing plants located? Toyota has numerous manufacturing plants located around the world, playing a crucial role in its global output, with key facilities in Japan, North America, and Asia.

4.1. Overview of Global Manufacturing Locations

Toyota operates manufacturing plants in over 25 countries, strategically located to serve regional markets and optimize supply chains. Major manufacturing hubs include:

- Japan: The heart of Toyota’s manufacturing operations, with numerous plants producing a wide range of models.

- North America: A significant production region, with plants in the United States, Canada, and Mexico.

- Asia: Key production centers in China, Thailand, Indonesia, and India.

- Europe: Manufacturing facilities in the United Kingdom, France, and Turkey.

- South America: Plants in Brazil and Argentina serving the Latin American market.

4.2. Production Capacity by Region

The production capacity of Toyota’s manufacturing plants varies by region. Japan remains the largest production hub, followed by North America and Asia. The United States, for example, has several large Toyota plants that contribute significantly to the company’s overall output. Each region tailors its production to meet local market demands.

4.3. Key Manufacturing Plants and Their Output

Some of Toyota’s key manufacturing plants include:

- Tahara Plant (Japan): Known for producing high-end models like the Lexus.

- Toyota Motor Manufacturing Kentucky (USA): One of the largest Toyota plants in North America, producing popular models like the Camry and Avalon.

- Guang汽丰田 Plant (China): A major production hub in China, manufacturing models for the Chinese market.

- Siam Toyota Manufacturing (Thailand): A key production base in Southeast Asia, producing vehicles for both domestic and export markets.

Each of these plants contributes significantly to Toyota’s daily car production, ensuring a steady supply of vehicles to meet global demand.

4.4. Technological Integration in Plants

Toyota’s manufacturing plants are equipped with advanced technologies to enhance efficiency and quality. Automation, robotics, and data analytics are integral to the production process. For example, robots perform repetitive tasks with precision, while data analytics helps optimize workflows and identify potential issues. This technological integration allows Toyota to maintain high production standards and reduce waste.

4.5. Environmental Sustainability Initiatives

Toyota is committed to environmental sustainability and has implemented various initiatives in its manufacturing plants to reduce their environmental impact. These initiatives include:

- Reducing energy consumption: Using energy-efficient equipment and optimizing energy usage.

- Minimizing water usage: Implementing water recycling systems and reducing water waste.

- Reducing waste: Recycling materials and minimizing waste sent to landfills.

- Lowering emissions: Using cleaner energy sources and reducing emissions from manufacturing processes.

These sustainability efforts not only help protect the environment but also enhance Toyota’s reputation as a responsible corporate citizen.

5. The Toyota Lineup: Models and Production Numbers

What Toyota models contribute most to daily production numbers? Popular Toyota models such as the Corolla, Camry, and RAV4 significantly contribute to daily production numbers, driven by global demand and market preferences.

5.1. Overview of Toyota’s Model Range

Toyota offers a diverse range of models to cater to various customer needs and preferences. The lineup includes:

- Sedans: Corolla, Camry, Avalon

- SUVs: RAV4, Highlander, 4Runner

- Trucks: Tacoma, Tundra

- Hybrids: Prius, Camry Hybrid, RAV4 Hybrid

- Electric Vehicles: bZ4X

- Minivans: Sienna

This broad range allows Toyota to appeal to a wide customer base, driving sales and production volumes.

5.2. Production Volume by Model

Certain Toyota models are produced in higher volumes due to their popularity and market demand. The Corolla, Camry, and RAV4 are consistently among the best-selling models globally, contributing significantly to Toyota’s daily production numbers.

| Model | Estimated Daily Production |

|---|---|

| Corolla | 6,000 |

| Camry | 5,000 |

| RAV4 | 4,500 |

| Tacoma | 2,000 |

| Tundra | 1,500 |

These figures illustrate the importance of these models to Toyota’s overall production output.

5.3. Factors Driving Model Popularity

Several factors drive the popularity of Toyota models:

- Reliability: Toyota is known for producing reliable vehicles that last for years.

- Fuel Efficiency: Many Toyota models offer excellent fuel economy, appealing to cost-conscious consumers.

- Safety: Toyota vehicles are equipped with advanced safety features, providing peace of mind to drivers and passengers.

- Value: Toyota offers competitive pricing and a strong resale value.

- Innovation: Toyota continuously introduces new technologies and features in its vehicles.

These factors contribute to the strong demand for Toyota models, driving production volumes.

5.4. Hybrid and Electric Vehicle Production

Toyota has been a pioneer in hybrid technology and is now expanding its electric vehicle lineup. The Prius remains a popular hybrid model, while the new bZ4X represents Toyota’s entry into the electric vehicle market. As demand for hybrid and electric vehicles grows, Toyota is increasing production of these models to meet consumer demand.

5.5. Customization and Special Editions

Toyota offers various customization options and special editions to appeal to specific customer preferences. This includes different trim levels, colors, and optional features. Special editions, such as the TRD Pro versions of the Tacoma and 4Runner, cater to off-road enthusiasts and add to the diversity of Toyota’s lineup.

6. How Toyota Meets Demand in the Boise Area

How does Miller Toyota in Boise ensure adequate supply? Miller Toyota in Boise ensures an adequate supply of vehicles by leveraging Toyota’s efficient distribution network and tailoring inventory to meet local customer demands.

6.1. Local Market Preferences in Boise

In the Boise area, certain Toyota models are particularly popular due to local market preferences. Reliable and fuel-efficient vehicles like the RAV4, Camry, and Tacoma are in high demand. Miller Toyota understands these preferences and stocks its inventory accordingly. According to customer satisfaction surveys in Boise, Idaho, in July 2025, Toyota provides reliability with Z%.

6.2. Miller Toyota’s Inventory Management

Miller Toyota employs effective inventory management strategies to ensure that it has the right vehicles in stock to meet customer demand. This involves:

- Monitoring sales trends: Tracking which models and trims are selling well.

- Analyzing customer feedback: Understanding what customers are looking for in a vehicle.

- Working closely with Toyota: Coordinating with Toyota to ensure a steady supply of vehicles.

- Adjusting inventory levels: Modifying inventory based on market conditions and customer demand.

By carefully managing its inventory, Miller Toyota can provide customers with a wide selection of vehicles and minimize wait times.

6.3. Special Orders and Customization Options

For customers who have specific requirements or want to customize their vehicle, Miller Toyota offers special order options. This allows customers to configure their vehicle exactly to their specifications, choosing the trim level, color, and optional features they desire.

6.4. Availability of New and Used Vehicles

Miller Toyota offers both new and used vehicles to cater to different budgets and preferences. The dealership maintains a diverse inventory of new Toyota models, as well as a selection of certified pre-owned vehicles that have been thoroughly inspected and reconditioned.

6.5. Financing and Leasing Options

To make Toyota vehicles more accessible, Miller Toyota provides a range of financing and leasing options. The dealership works with various lenders to offer competitive interest rates and flexible payment plans. Leasing options are also available for customers who prefer lower monthly payments and the ability to upgrade to a new vehicle every few years.

7. Maintaining Quality and Reliability in Production

How does Toyota ensure quality and reliability in vehicle production? Toyota ensures quality and reliability through rigorous testing, adherence to high manufacturing standards, and continuous improvement processes embedded in its production system.

7.1. Rigorous Testing Procedures

Toyota employs rigorous testing procedures throughout the production process to ensure that each vehicle meets high standards of quality and reliability. This includes:

- Component testing: Testing individual components to ensure they meet specifications.

- Vehicle testing: Testing the entire vehicle under various conditions to identify potential issues.

- Durability testing: Testing the vehicle’s long-term durability and reliability.

- Safety testing: Testing safety features to ensure they function properly.

These testing procedures help Toyota identify and address any potential issues before the vehicles reach customers.

7.2. Adherence to Manufacturing Standards

Toyota adheres to strict manufacturing standards to ensure consistency and quality in its production process. This includes:

- ISO certifications: Maintaining ISO certifications for quality management and environmental management.

- Standardized processes: Using standardized processes to ensure consistency across all manufacturing plants.

- Quality control checks: Implementing quality control checks at every stage of the production process.

By adhering to these standards, Toyota can maintain high levels of quality and reliability in its vehicles.

7.3. Continuous Improvement Processes

Toyota’s commitment to continuous improvement (Kaizen) extends to its quality control processes. The company continuously seeks ways to improve its manufacturing processes and enhance the quality of its vehicles. This includes:

- Analyzing data: Tracking quality data to identify trends and potential issues.

- Implementing corrective actions: Taking corrective actions to address any identified issues.

- Improving processes: Continuously improving manufacturing processes to prevent future issues.

By continuously improving its quality control processes, Toyota can enhance the reliability and durability of its vehicles.

7.4. Employee Training and Empowerment

Toyota invests heavily in training its employees to ensure they have the skills and knowledge to produce high-quality vehicles. The company also empowers its employees to identify and address quality issues. This includes:

- Training programs: Providing comprehensive training programs for all employees.

- Empowerment: Empowering employees to stop the production line if they identify a quality issue.

- Feedback mechanisms: Implementing feedback mechanisms to gather input from employees on how to improve quality.

By investing in its employees and empowering them to take ownership of quality, Toyota can maintain high standards of quality and reliability.

7.5. Supplier Quality Management

Toyota works closely with its suppliers to ensure that they meet the company’s high standards of quality. This includes:

- Supplier audits: Conducting regular audits of suppliers to assess their quality control processes.

- Training programs: Providing training programs for suppliers to help them improve their quality.

- Collaboration: Collaborating with suppliers to identify and address quality issues.

By working closely with its suppliers, Toyota can ensure that the components used in its vehicles meet high standards of quality and reliability.

8. The Future of Toyota’s Production

What are Toyota’s plans for future production and innovation? Toyota plans to increase electric vehicle production and invest in sustainable manufacturing, while continuing to innovate in hybrid technology and autonomous driving.

8.1. Expansion of Electric Vehicle Production

Toyota is committed to expanding its electric vehicle (EV) lineup and increasing EV production. The company plans to introduce several new EV models in the coming years and is investing heavily in battery technology to improve the range and performance of its EVs. As demand for electric vehicles grows, Toyota aims to become a leader in the EV market.

8.2. Investment in Sustainable Manufacturing

Toyota is investing in sustainable manufacturing practices to reduce its environmental impact. This includes:

- Reducing energy consumption: Using renewable energy sources and implementing energy-efficient technologies in its manufacturing plants.

- Minimizing water usage: Implementing water recycling systems and reducing water waste.

- Reducing waste: Recycling materials and minimizing waste sent to landfills.

- Lowering emissions: Using cleaner energy sources and reducing emissions from manufacturing processes.

By investing in sustainable manufacturing, Toyota aims to reduce its environmental footprint and contribute to a more sustainable future.

8.3. Continued Innovation in Hybrid Technology

Toyota remains committed to hybrid technology and is continuing to innovate in this area. The company plans to introduce new hybrid models and improve the performance and efficiency of its existing hybrid vehicles. Toyota believes that hybrid technology will play a key role in reducing emissions and improving fuel economy in the coming years.

8.4. Development of Autonomous Driving Technology

Toyota is actively developing autonomous driving technology and plans to introduce autonomous driving features in its vehicles in the future. The company is investing in research and development to improve the safety and reliability of its autonomous driving systems. Toyota believes that autonomous driving technology has the potential to improve safety, reduce traffic congestion, and enhance mobility for all.

8.5. Adapting to Changing Market Demands

Toyota is committed to adapting to changing market demands and customer preferences. The company continuously monitors market trends and adjusts its production plans accordingly. This includes:

- Responding to customer feedback: Gathering feedback from customers and using it to improve its products and services.

- Monitoring competitor activity: Tracking what competitors are doing and adapting its strategies accordingly.

- Investing in new technologies: Investing in new technologies to stay ahead of the curve.

By adapting to changing market demands, Toyota can remain competitive and continue to meet the needs of its customers.

9. Visiting Miller Toyota in Boise: Your Local Toyota Resource

Why visit Miller Toyota in Boise for your Toyota needs? Miller Toyota in Boise offers personalized service, a wide selection of vehicles, and expert maintenance, making it the premier local resource for all Toyota needs.

9.1. Wide Selection of New and Used Vehicles

Miller Toyota offers a wide selection of new and used Toyota vehicles to cater to different budgets and preferences. Whether you are looking for a new RAV4, Camry, Tacoma, or another Toyota model, you are likely to find it at Miller Toyota. The dealership also offers a selection of certified pre-owned vehicles that have been thoroughly inspected and reconditioned.

9.2. Expert Service and Maintenance

Miller Toyota has a team of expert technicians who can provide top-notch service and maintenance for your Toyota vehicle. Whether you need an oil change, tire rotation, brake repair, or another service, the technicians at Miller Toyota can get the job done right. The dealership also uses genuine Toyota parts to ensure the quality and reliability of its service.

9.3. Financing and Leasing Options

Miller Toyota offers a range of financing and leasing options to make Toyota vehicles more accessible. The dealership works with various lenders to offer competitive interest rates and flexible payment plans. Leasing options are also available for customers who prefer lower monthly payments and the ability to upgrade to a new vehicle every few years.

9.4. Personalized Customer Service

Miller Toyota is committed to providing personalized customer service to each and every customer. The dealership’s friendly and knowledgeable staff can help you find the right vehicle, answer your questions, and guide you through the buying process. Miller Toyota also provides ongoing support and assistance after the sale to ensure your satisfaction.

9.5. Convenient Location and Hours

Miller Toyota is conveniently located at 208 N Maple Grove Rd, Boise, ID 83704, United States. The dealership also offers convenient hours to accommodate busy schedules. You can visit Miller Toyota during the following hours:

- Monday – Friday: 9:00 AM – 8:00 PM

- Saturday: 9:00 AM – 7:00 PM

- Sunday: 10:00 AM – 6:00 PM

You can also contact Miller Toyota by phone at +1 (208) 376-8888 or visit their website at millertoyota.net.

10. FAQs About Toyota Production

10.1. How many cars does Toyota produce a day?

Toyota produces approximately 24,000 cars per day worldwide, making them the leading car manufacturer in terms of daily output.

10.2. Which Toyota models are produced in the highest volumes?

The Toyota Corolla, Camry, and RAV4 are produced in the highest volumes due to their global popularity and strong market demand.

10.3. What is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is a management philosophy focused on minimizing waste and maximizing efficiency in the manufacturing process.

10.4. How does Toyota ensure quality and reliability in its vehicles?

Toyota ensures quality and reliability through rigorous testing procedures, adherence to strict manufacturing standards, and continuous improvement processes.

10.5. Where are Toyota’s major manufacturing plants located?

Toyota has major manufacturing plants located in Japan, North America, Asia, Europe, and South America.

10.6. How does Miller Toyota in Boise ensure an adequate supply of vehicles?

Miller Toyota in Boise ensures an adequate supply of vehicles by leveraging Toyota’s efficient distribution network and tailoring inventory to meet local customer demands.

10.7. What are Toyota’s plans for the future of electric vehicle production?

Toyota plans to expand its electric vehicle lineup and increase EV production in the coming years, investing heavily in battery technology.

10.8. How can I order a customized Toyota vehicle?

You can order a customized Toyota vehicle through Miller Toyota in Boise, specifying the trim level, color, and optional features you desire.

10.9. What financing options are available at Miller Toyota?

Miller Toyota offers a range of financing and leasing options to make Toyota vehicles more accessible, working with various lenders to offer competitive rates and flexible payment plans.

10.10. Where can I find more information about Toyota vehicles and services in Boise?

You can find more information about Toyota vehicles and services in Boise by visiting Miller Toyota’s website at millertoyota.net or contacting them by phone at +1 (208) 376-8888.

Ready to experience the quality and reliability of a Toyota? Visit millertoyota.net today to explore our wide selection of vehicles, schedule a service appointment, or contact our friendly staff for personalized assistance. Discover why Toyota is a global leader in automotive manufacturing and how Miller Toyota in Boise can meet all of your automotive needs.