Are Toyotas Assembled In Usa? Absolutely! Toyota has significantly invested in American manufacturing, and millertoyota.net is your premier Boise resource for discovering these vehicles, offering comprehensive information and exceptional service. Explore our selection of American-made Toyotas and experience the quality and reliability that Toyota and Miller Toyota are known for.

1. What Toyota Models Are Assembled in the USA?

Several popular Toyota models are proudly assembled in the United States. Currently, Toyota manufactures a range of vehicles in its North American facilities, including the Camry, Tundra, Sequoia, and Tacoma, showcasing Toyota’s commitment to American manufacturing and providing reliable options for drivers in Boise and beyond and are always looking for auto repair. For the most up-to-date list and specific trim information, check millertoyota.net.

American-Assembled Toyota Models

| Model | Type |

|---|---|

| Camry | Sedan |

| Tundra | Truck |

| Sequoia | SUV |

| Tacoma | Truck |

Toyota Tundra Plant Texas

Toyota Tundra Plant Texas

2. Where Are Toyota Manufacturing Plants Located in the USA?

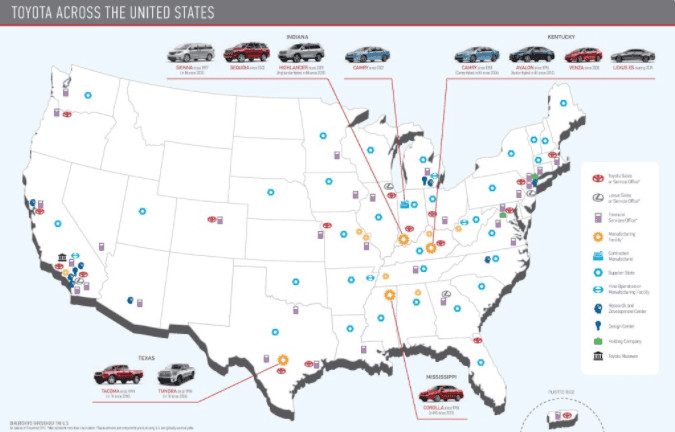

Toyota has established several manufacturing plants across the United States. Toyota’s manufacturing facilities are strategically located in states such as Kentucky, Indiana, Mississippi, and Texas. These plants contribute significantly to the American economy and provide jobs for thousands of workers. These locations include:

- Kentucky: Toyota Motor Manufacturing Kentucky, Inc. (TMMK)

- Indiana: Toyota Motor Manufacturing Indiana, Inc. (TMMI)

- Mississippi: Toyota Motor Manufacturing Mississippi (TMMMS)

- Texas: Toyota Motor Manufacturing Texas, Inc. (TMMTX)

2.1 What is Toyota Motor Manufacturing Kentucky, Inc. (TMMK)?

Toyota Motor Manufacturing Kentucky, Inc. (TMMK), established in 1986, holds the distinction of being Toyota’s first wholly-owned U.S.-based manufacturing plant, solidifying Toyota’s presence in the American automotive market. It stands as the largest Toyota manufacturing facility outside of Japan, demonstrating the scale of Toyota’s investment in U.S. production. TMMK produces popular models such as the Camry and Avalon, as well as hybrid versions of these vehicles, reflecting Toyota’s commitment to both traditional and environmentally-friendly vehicle options. This plant exemplifies Toyota’s dedication to quality and innovation in American manufacturing.

2.2 What is Toyota Motor Manufacturing Indiana, Inc. (TMMI)?

Toyota Motor Manufacturing Indiana, Inc. (TMMI), established in 1996 and located in Gibson County, Indiana, initially focused on producing full-size pickup trucks for the American market. TMMI has expanded its production to include popular SUVs like the Highlander and Sequoia, demonstrating its adaptability to changing consumer demands. TMMI plays a crucial role in Toyota’s North American production strategy, contributing significantly to the company’s overall output. For more details on current models and production capabilities, visit millertoyota.net.

2.3 What is Toyota Motor Manufacturing Mississippi (TMMMS)?

Toyota Motor Manufacturing Mississippi (TMMMS), located in Blue Springs, Mississippi, began operations in 2011 with the production of the Corolla, one of Toyota’s best-selling models. TMMMS represents Toyota’s continued investment in American manufacturing and its commitment to producing high-quality, fuel-efficient vehicles. The plant’s focus on the Corolla highlights Toyota’s dedication to meeting the needs of American consumers with reliable and affordable transportation options. Contact millertoyota.net for expert advice on car maintenance.

2.4 What is Toyota Motor Manufacturing Texas, Inc. (TMMTX)?

Toyota Motor Manufacturing Texas, Inc. (TMMTX), acquired by Toyota in 2003 and located in San Antonio, Texas, specializes in manufacturing Toyota full-size pickup trucks, including the Tacoma and Tundra, catering to the robust demand for trucks in the American market. TMMTX is a cornerstone of Toyota’s truck production in North America, contributing significantly to the company’s overall sales and market presence. The facility’s focus on trucks underscores Toyota’s commitment to providing durable and capable vehicles for American consumers.

3. Why Does It Matter Where My Toyota Is Assembled?

Knowing where your Toyota is assembled can be important for several reasons. A vehicle assembled in the USA supports the local economy by creating jobs and keeping revenue within the country, reflecting an investment in the community. Choosing a domestically assembled vehicle can sometimes offer advantages in terms of parts availability and potentially lower shipping costs, making maintenance and repairs more convenient. Many consumers prefer to support American manufacturing due to a sense of patriotism and a desire to contribute to the growth of the national economy.

- Supporting the local economy

- Parts availability

- Patriotism

4. How Does Toyota Contribute to the American Economy Through Manufacturing?

Toyota’s manufacturing operations in the USA have a significant positive impact on the American economy. Toyota directly employs tens of thousands of Americans across its manufacturing plants, research and development facilities, and corporate offices. Through its extensive supply chain, Toyota supports hundreds of thousands of additional jobs at American companies that provide parts, materials, and services to Toyota’s operations. Toyota has invested billions of dollars in its American manufacturing facilities, demonstrating a long-term commitment to the U.S. economy.

4.1 How many people are employed?

Toyota directly employs over 36,000 people in the United States, contributing significantly to job creation and economic stability across various states. These employees work in a range of roles, from manufacturing and engineering to sales and marketing, supporting diverse communities. Beyond direct employment, Toyota’s presence in the U.S. supports an additional 300,000 jobs through its supply chain and related industries, amplifying its economic impact. For more information about career opportunities and Toyota’s economic contributions, explore resources on millertoyota.net.

4.2 How much has Toyota invested in US manufacturing?

Toyota has invested over $28 billion in its U.S. manufacturing facilities, demonstrating a strong commitment to American production and economic growth. This substantial investment has facilitated the establishment and expansion of numerous plants, research and development centers, and corporate offices across the country. The ongoing investments reflect Toyota’s dedication to innovation, job creation, and the production of high-quality vehicles for the American market. To learn more about Toyota’s investments and future plans, visit millertoyota.net.

4.3 What is the economic impact?

Toyota’s economic impact in the U.S. is substantial, contributing billions of dollars to the nation’s GDP annually through manufacturing, sales, and related activities. The company’s operations support hundreds of thousands of jobs, both directly and indirectly, benefiting families and communities across the country. Toyota’s commitment to local communities extends beyond economic contributions through philanthropic efforts and partnerships with educational institutions, further enhancing its positive influence. Explore millertoyota.net for updates on Toyota’s community initiatives.

5. Are There Any Benefits to Buying a Toyota Assembled in the USA?

Yes, buying a Toyota assembled in the USA can offer several benefits. Supporting American manufacturing helps to create and sustain jobs within the United States, boosting the economy. Domestically assembled vehicles often have easier access to parts, which can simplify maintenance and repairs, potentially reducing costs and downtime. Many buyers feel a sense of pride in supporting American workers and industries by choosing a vehicle made in the USA.

- Supporting American jobs

- Easier access to parts

- Pride in supporting American workers

6. How Can I Find Out Where My Toyota Was Assembled?

Determining where your Toyota was assembled is typically straightforward. The Vehicle Identification Number (VIN), a unique 17-character code assigned to every vehicle, contains information about the vehicle’s origin. The first character of the VIN indicates the country of origin; for example, a VIN starting with “1,” “4,” or “5” indicates that the vehicle was manufactured in the United States. The VIN can usually be found on the driver’s side dashboard, visible through the windshield, or on a sticker located on the driver’s side doorjamb. Once you have the VIN, you can use online VIN decoders or contact Toyota directly to obtain detailed information about your vehicle’s assembly location.

6.1 How do I use the VIN?

To use the Vehicle Identification Number (VIN) to determine where your Toyota was assembled, locate the VIN on your vehicle’s dashboard or doorjamb. The first character of the VIN indicates the country of origin; a “1,” “4,” or “5” signifies that the vehicle was assembled in the United States. Use an online VIN decoder tool or contact Toyota directly, providing the VIN to receive detailed information about your vehicle’s manufacturing location. For assistance with VIN decoding or other vehicle inquiries, visit millertoyota.net.

6.2 Where do I locate the VIN on the vehicle?

You can typically find the Vehicle Identification Number (VIN) in two primary locations on your Toyota vehicle. The most common location is on the driver’s side dashboard, visible through the windshield. Additionally, the VIN is usually printed on a sticker located on the driver’s side doorjamb. These locations provide easy access to the VIN for identification and verification purposes. If you need help locating the VIN or have further questions, reach out to millertoyota.net for assistance.

7. Does Assembled in USA Mean 100% American Made?

No, “Assembled in USA” does not necessarily mean that a vehicle is 100% American-made. While the final assembly takes place in the United States, the vehicle may contain parts and components sourced from other countries. The percentage of American-made parts can vary significantly from model to model. The American Automobile Labeling Act (AALA) requires automakers to disclose the percentage of U.S. and Canadian parts in their vehicles.

7.1 What is the American Automobile Labeling Act (AALA)?

The American Automobile Labeling Act (AALA) mandates that automakers disclose the percentage of U.S. and Canadian parts in their vehicles, promoting transparency for consumers. Automakers must include this information on a sticker affixed to the vehicle’s window, allowing buyers to make informed decisions about their purchase. The AALA aims to encourage manufacturers to increase the use of domestic parts, thereby supporting the American economy. For more detailed information about the AALA and vehicle labeling, visit millertoyota.net.

7.2 How can I find the percentage of American-made parts in my Toyota?

To find the percentage of American-made parts in your Toyota, check the window sticker of the vehicle, which is required by the American Automobile Labeling Act (AALA) to display this information. The sticker lists the percentage of U.S. and Canadian parts used in the vehicle, providing transparency for consumers. If you no longer have the window sticker, you may be able to find this information on the manufacturer’s website or by contacting Toyota directly. For any assistance or additional information, feel free to contact millertoyota.net.

8. How Does Toyota Ensure Quality in Its American Manufacturing Plants?

Toyota maintains rigorous quality control standards in all of its manufacturing plants, including those in the USA. The company employs a comprehensive quality management system known as the Toyota Production System (TPS), which emphasizes continuous improvement and defect prevention. Toyota invests heavily in training its employees in the principles of TPS and quality control techniques. Regular audits and inspections are conducted to ensure that all plants meet Toyota’s high standards for quality and reliability.

8.1 What is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is a comprehensive management philosophy and set of practices focused on continuous improvement and efficiency in manufacturing. TPS emphasizes the elimination of waste, respect for people, and a commitment to ongoing learning and development. Key principles of TPS include just-in-time production, autonomation (automation with a human touch), and continuous improvement (Kaizen). For more information on TPS and its impact on Toyota’s quality, explore resources on millertoyota.net.

8.2 What kind of training do employees receive?

Toyota employees receive extensive training in the Toyota Production System (TPS) and various quality control techniques, ensuring they are well-equipped to maintain high standards. Training programs cover topics such as problem-solving, teamwork, and continuous improvement (Kaizen) methodologies, fostering a culture of excellence. Toyota invests in ongoing training and development opportunities to keep employees updated with the latest technologies and best practices. For more information about Toyota’s employee training programs and career opportunities, visit millertoyota.net.

9. What Are Some Common Misconceptions About Foreign Automakers Manufacturing in the USA?

There are several common misconceptions about foreign automakers manufacturing in the USA. One misconception is that these plants primarily employ foreign workers; in reality, the vast majority of employees are American citizens. Another misconception is that the quality of vehicles produced in American plants is lower than those produced in the automaker’s home country; however, Toyota maintains the same high quality standards in all of its plants worldwide. Some people also believe that these companies don’t contribute significantly to the American economy, but as mentioned earlier, Toyota’s investments and operations have a substantial positive impact.

- Plants employ mostly foreign workers

- Lower quality vehicles

- Minimal economic contribution

10. How Can I Stay Up-to-Date on Toyota’s Manufacturing Operations in the USA?

Staying informed about Toyota’s manufacturing operations in the USA is easy with various resources available. Regularly visiting Toyota’s official website provides updates on new investments, production milestones, and employment opportunities. Following Toyota’s official social media channels on platforms like Twitter, Facebook, and LinkedIn ensures you receive timely announcements and news. Subscribing to industry publications and news outlets that cover the automotive sector keeps you informed about broader trends and developments affecting Toyota and other manufacturers. For local updates and information, keep checking millertoyota.net.

- Toyota’s official website

- Social media channels

- Industry publications

By choosing a Toyota assembled in the USA, you’re not just getting a reliable vehicle; you’re also supporting American jobs and contributing to the U.S. economy. Explore the selection at millertoyota.net today!

Ready to experience the quality of a Toyota assembled in the USA? Visit millertoyota.net to explore our inventory, schedule a test drive, and learn more about our commitment to serving the Boise community. Contact us today and let us help you find the perfect Toyota to fit your needs!

Address: 208 N Maple Grove Rd, Boise, ID 83704, United States

Phone: +1 (208) 376-8888

Website: millertoyota.net

FAQ: Toyota Assembly in the USA

1. Are All Toyota Models Sold in the US Assembled Here?

No, not all Toyota models sold in the US are assembled here; some are imported from Japan and other countries, as Toyota distributes its manufacturing globally to optimize production and meet diverse market demands. At millertoyota.net, we can help you identify which models are US-assembled.

2. Does Assembling Cars in the US Mean They Are Cheaper?

Not necessarily, assembling cars in the US does not automatically make them cheaper, as production costs also depend on factors like labor expenses, component sourcing, and logistical considerations. However, millertoyota.net strives to offer competitive pricing on all models, regardless of assembly location.

3. How Many Toyota Plants Are There in the United States?

There are currently four major Toyota manufacturing plants in the United States, located in Kentucky, Indiana, Mississippi, and Texas, strategically positioned to support the production of a variety of models. Visit millertoyota.net for detailed information about each plant and the models they produce.

4. Can I Tour a Toyota Manufacturing Plant in the USA?

Yes, public tours of Toyota manufacturing plants in the USA may be available, offering a firsthand look at the assembly process and the company’s commitment to quality and innovation. Contact millertoyota.net to learn more about tour availability and how to schedule a visit.

5. Do US-Assembled Toyotas Have Better Resale Value?

The resale value of US-assembled Toyotas is influenced by various factors, including the vehicle’s condition, mileage, and market demand, rather than solely its assembly location, though supporting the local economy can indirectly boost demand. Check with millertoyota.net for insights on the resale values of different Toyota models.

6. Are the Parts Used in US-Assembled Toyotas Also American-Made?

Not always, the parts used in US-assembled Toyotas are not always entirely American-made; a mix of domestic and foreign components are used, with the percentage of American-made parts varying by model. millertoyota.net provides detailed information on the composition of specific Toyota vehicles.

7. How Does Toyota Ensure Safety Standards in Its US Plants?

Toyota ensures stringent safety standards in all its US plants through rigorous training programs, advanced technology integration, and continuous monitoring to protect employees and maintain high production quality. At millertoyota.net, we emphasize that safety is a core value in every aspect of Toyota’s operations.

8. Does Buying a US-Assembled Toyota Reduce My Carbon Footprint?

Potentially, buying a US-assembled Toyota may reduce your carbon footprint, as it minimizes transportation emissions compared to importing vehicles from overseas, supporting environmental sustainability. Learn more about Toyota’s green initiatives and eco-friendly vehicles at millertoyota.net.

9. What Quality Awards Have Toyota’s US Plants Received?

Toyota’s US plants have received numerous quality awards, reflecting their commitment to excellence in manufacturing and demonstrating the effectiveness of the Toyota Production System in maintaining high standards. Visit millertoyota.net for updates on the latest accolades and recognitions earned by Toyota’s US facilities.

10. How Do I Find a Toyota Made in the USA at Miller Toyota?

Finding a Toyota made in the USA at Miller Toyota is easy; our knowledgeable sales team can provide you with specific information on the assembly location of any model, ensuring you can make an informed decision. Contact us or visit millertoyota.net to explore our inventory of US-assembled vehicles and find the perfect Toyota for your needs.