Where Do Toyotas Come From? Toyotas are manufactured in various locations worldwide, including Japan, the United States, and other countries, and at millertoyota.net, we’re committed to providing you with the best information and service for your Toyota needs. Learn about Toyota’s commitment to quality and innovation, and explore our wide selection of vehicles and services today. We focus on quality, reliability, and customer satisfaction, offering a wide selection of vehicles and services.

1. What Countries Manufacture Toyotas?

Toyota vehicles are manufactured in several countries around the world. Toyota has a global manufacturing footprint, with production facilities in Japan, the United States, Canada, Mexico, and various other countries. The specific manufacturing location can vary depending on the model and the intended market.

Toyota’s global production strategy ensures that it can efficiently meet the diverse needs of customers worldwide, while also contributing to local economies. Toyota produces vehicles in many countries, including Japan, the USA, and others. This multinational approach allows Toyota to tailor production to regional demands, optimize supply chains, and support local economies.

1.1. What Are Toyota’s Key Manufacturing Locations Globally?

Toyota’s key manufacturing locations globally include Japan, North America (United States, Canada, and Mexico), Asia (including China, Thailand, and Indonesia), and Europe (United Kingdom, France, and Turkey). These locations strategically position Toyota to serve major markets and leverage regional expertise.

These plants focus on producing different models and components, ensuring a steady supply of vehicles and parts to meet global demand. Toyota also focuses on sustainability in these locations by reducing environmental impact and supporting local communities through job creation and community outreach programs. These manufacturing hubs allow Toyota to stay agile and competitive in the worldwide automotive market.

1.2. Does Toyota Manufacture Cars in the USA?

Yes, Toyota manufactures cars in the USA. Toyota has several manufacturing facilities across the United States that produce a range of popular models.

Toyota’s investment in American manufacturing facilities highlights its commitment to the U.S. market. These facilities produce popular models such as the Camry, Corolla, Highlander, and Tundra, contributing significantly to the U.S. economy through job creation and local investment. According to the Toyota USA Newsroom, Toyota has invested over $28.4 billion in its U.S. manufacturing facilities, employing over 47,000 people. This investment supports not only the production of vehicles but also research and development activities aimed at enhancing vehicle performance and sustainability.

Toyota Manufacturing Plant

Toyota Manufacturing Plant

2. Which Toyota Models Are Made in America?

Several Toyota models are made in America. Toyota manufactures a range of popular vehicles in its U.S. plants, including the Camry, Tundra, Highlander, and Sequoia.

Here is a brief overview of some models made in America:

-

Camry: The Toyota Camry has been a staple of American roads for decades, known for its reliability and efficiency.

-

Tundra: The Toyota Tundra is a full-size pickup truck that combines rugged performance with advanced technology, making it a popular choice for both work and leisure.

-

Highlander: The Toyota Highlander is a mid-size SUV that offers a comfortable and spacious interior, making it ideal for families.

-

Sequoia: The Toyota Sequoia is a full-size SUV that provides ample space and powerful performance, perfect for adventurous families.

These models are manufactured in various Toyota plants across the United States, contributing to local economies and providing jobs for thousands of Americans. According to a 2023 study by the Center for Automotive Research, Toyota’s U.S. manufacturing operations support over 640,000 jobs across the country, including direct employment and jobs in supplier and distribution networks.

3. Where Are Toyota Manufacturing Plants Located in the USA?

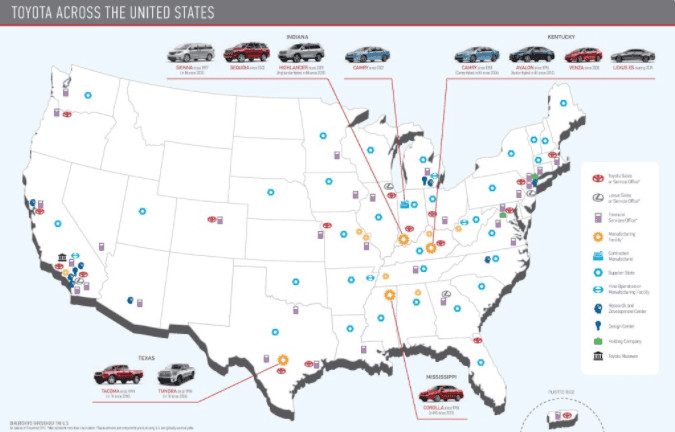

Toyota’s manufacturing plants in the USA are strategically located in several states. Key locations include Kentucky, Indiana, Texas, Mississippi, and Alabama.

These locations allow Toyota to efficiently produce and distribute vehicles across the country. Each plant specializes in different models and components, contributing to Toyota’s diverse product lineup. These strategic locations enhance Toyota’s ability to meet customer demand and support local economies.

3.1. What Is the Role of Toyota Motor Manufacturing Kentucky (TMMK)?

Toyota Motor Manufacturing Kentucky (TMMK) plays a crucial role in Toyota’s North American operations. TMMK, located in Georgetown, Kentucky, is Toyota’s largest manufacturing facility in North America. It produces some of Toyota’s most popular models, including the Camry, Camry Hybrid, and Avalon.

TMMK was Toyota’s first wholly-owned U.S. manufacturing plant, established in 1986, and it remains one of the company’s most important production hubs. TMMK also emphasizes sustainable manufacturing practices, reducing its environmental impact through energy efficiency and waste reduction initiatives. The facility has received numerous awards for its commitment to environmental stewardship and community involvement.

3.2. What Is Produced at Toyota Motor Manufacturing Indiana (TMMI)?

Toyota Motor Manufacturing Indiana (TMMI) primarily produces SUVs and minivans. Located in Princeton, Indiana, TMMI is responsible for manufacturing the Toyota Highlander, Sequoia, and Sienna.

The plant focuses on producing vehicles that meet the needs of families and individuals looking for space, comfort, and reliability. TMMI also focuses on continuous improvement and innovation, implementing advanced manufacturing technologies to enhance production efficiency and vehicle quality. The Indiana plant plays a crucial role in Toyota’s North American production strategy.

3.3. What Is the Significance of Toyota Motor Manufacturing Mississippi (TMMMS)?

Toyota Motor Manufacturing Mississippi (TMMMS) is significant for producing the Toyota Corolla. Located in Blue Springs, Mississippi, TMMMS plays a vital role in meeting the demand for this popular compact car.

TMMMS exemplifies Toyota’s commitment to investing in local communities and creating job opportunities. The Mississippi plant also implements sustainable manufacturing practices, such as reducing water consumption and minimizing waste, contributing to Toyota’s overall environmental goals. TMMMS is a key component of Toyota’s North American production network, ensuring a steady supply of Corollas to meet customer demand.

3.4. What Is the Focus of Toyota Motor Manufacturing Texas (TMMTX)?

Toyota Motor Manufacturing Texas (TMMTX) focuses on producing pickup trucks. Located in San Antonio, Texas, TMMTX is responsible for manufacturing the Toyota Tundra and Tacoma.

TMMTX is also committed to community engagement, supporting local educational programs and charitable organizations. The Texas plant is a vital part of Toyota’s North American production strategy, ensuring a steady supply of pickup trucks to meet customer demand in the United States and beyond. Its focus on trucks caters to a specific market segment, enhancing Toyota’s overall competitiveness.

4. How Does Toyota Ensure Quality in Manufacturing?

Toyota ensures quality in manufacturing through a comprehensive approach. This includes implementing the Toyota Production System (TPS), emphasizing continuous improvement (Kaizen), and rigorous quality control processes.

Toyota’s commitment to quality is evident in every stage of the manufacturing process, from design and engineering to production and inspection. By adhering to these principles, Toyota maintains high standards of quality and reliability in all its vehicles. According to J.D. Power’s 2023 U.S. Vehicle Dependability Study, Toyota vehicles consistently rank high in terms of reliability and customer satisfaction, demonstrating the effectiveness of their quality control processes.

4.1. What Is the Toyota Production System (TPS)?

The Toyota Production System (TPS) is a comprehensive manufacturing philosophy. TPS focuses on eliminating waste, improving efficiency, and ensuring quality at every stage of the production process.

The Toyota Production System also involves empowering employees to identify and solve problems, fostering a culture of continuous improvement. The core principles of TPS, such as Just-in-Time (JIT) and Jidoka (automation with a human touch), are designed to optimize production flow and minimize defects. TPS is a cornerstone of Toyota’s manufacturing excellence, enabling the company to produce high-quality vehicles efficiently and reliably.

4.2. How Does Toyota Implement Continuous Improvement (Kaizen)?

Toyota implements continuous improvement through Kaizen by encouraging all employees to identify and implement small, incremental improvements. Kaizen is a philosophy that emphasizes ongoing efforts to enhance processes, eliminate waste, and improve quality.

Kaizen events, where teams focus on specific areas for improvement, are a common practice. These efforts can lead to significant enhancements in productivity, quality, and safety over time. By fostering a culture of continuous improvement, Toyota ensures that its manufacturing processes remain efficient, effective, and adaptable to changing market conditions.

4.3. What Quality Control Processes Does Toyota Use?

Toyota uses rigorous quality control processes throughout its manufacturing operations. These processes include thorough inspections at each stage of production, statistical process control (SPC) to monitor and control variation, and comprehensive testing of finished vehicles.

Toyota’s quality control processes also involve advanced technologies such as automated inspection systems and data analytics to identify and address potential issues proactively. The company’s commitment to quality is reflected in its consistently high ratings in customer satisfaction surveys and reliability studies. By implementing these stringent quality control measures, Toyota ensures that its vehicles meet the highest standards of performance, safety, and durability.

5. What Are the Environmental Practices in Toyota Manufacturing?

Toyota is committed to sustainable environmental practices in its manufacturing operations. The company focuses on reducing waste, conserving energy, minimizing water usage, and lowering emissions.

Toyota’s environmental initiatives also include promoting recycling, using renewable energy sources, and designing vehicles with eco-friendly materials. By prioritizing environmental sustainability, Toyota aims to minimize its environmental footprint and contribute to a cleaner, healthier planet. According to Toyota’s Sustainability Report, the company has set ambitious targets for reducing carbon emissions, water consumption, and waste generation across its manufacturing facilities.

5.1. How Does Toyota Reduce Waste in Manufacturing?

Toyota reduces waste in manufacturing through various strategies. These include implementing the principles of the Toyota Production System (TPS), which emphasizes the elimination of all forms of waste (Muda), such as overproduction, waiting, and defects.

Toyota also focuses on waste reduction through recycling programs, reusing materials, and optimizing processes to minimize scrap and rework. By prioritizing waste reduction, Toyota enhances efficiency, lowers costs, and reduces its environmental impact. According to Toyota’s Environmental Challenge 2050, the company aims to achieve zero waste at all its manufacturing facilities worldwide.

5.2. What Energy Conservation Measures Are in Place?

Toyota has implemented several energy conservation measures in its manufacturing plants. These include using energy-efficient equipment, optimizing lighting and HVAC systems, and implementing energy management programs.

Toyota also invests in renewable energy sources such as solar power and wind energy to reduce its reliance on fossil fuels. By prioritizing energy conservation, Toyota lowers its operating costs and reduces its carbon footprint. Toyota’s commitment to energy conservation helps create a more sustainable future.

5.3. How Does Toyota Minimize Water Usage?

Toyota minimizes water usage in its manufacturing operations through various strategies. These include implementing water recycling systems, optimizing cooling processes, and using water-efficient equipment.

Toyota also focuses on reducing water consumption in landscaping and sanitation. By minimizing water usage, Toyota conserves valuable resources and reduces its environmental impact. The company’s efforts to reduce water consumption align with its broader commitment to environmental sustainability.

6. What Is the Impact of Toyota Manufacturing on Local Economies?

Toyota manufacturing has a significant positive impact on local economies. Toyota’s manufacturing facilities create jobs, stimulate economic growth, and support local communities through various initiatives.

Toyota’s presence in these communities also fosters workforce development, providing training and educational opportunities for local residents. According to a study by the Economic Policy Institute, Toyota’s manufacturing operations in the United States support thousands of jobs and generate billions of dollars in economic output annually.

6.1. How Many Jobs Does Toyota Manufacturing Create?

Toyota manufacturing creates numerous jobs in the regions where its plants are located. These jobs include direct employment at the manufacturing facilities, as well as indirect jobs in supplier industries, transportation, and other related sectors.

Toyota’s job creation efforts contribute to economic stability and prosperity in local communities. Toyota is a major employer in many states, providing stable, well-paying jobs with opportunities for advancement. The company’s commitment to job creation aligns with its broader mission of contributing to society and supporting local economies.

6.2. How Does Toyota Support Local Communities?

Toyota supports local communities through various initiatives. These include charitable donations, educational programs, and community development projects.

Toyota’s community support initiatives also focus on promoting environmental sustainability, fostering workforce development, and enhancing the quality of life for local residents. By investing in local communities, Toyota strengthens its relationships with stakeholders and contributes to the well-being of society.

6.3. What Educational Programs Does Toyota Offer?

Toyota offers various educational programs to support workforce development and promote STEM education. These programs include scholarships, internships, and training programs for students and employees.

Toyota’s educational programs also focus on promoting innovation, fostering creativity, and preparing individuals for careers in the automotive industry. By investing in education, Toyota helps build a skilled workforce and contributes to the long-term success of local communities.

7. How Does Toyota Incorporate Technology in Manufacturing?

Toyota incorporates advanced technology in its manufacturing processes to enhance efficiency, improve quality, and reduce costs. This includes using robotics, automation, and data analytics to optimize production and streamline operations.

Toyota’s technology initiatives also focus on promoting innovation, fostering collaboration, and enhancing the capabilities of its workforce. By embracing technology, Toyota remains at the forefront of manufacturing excellence and delivers high-quality vehicles to its customers.

7.1. What Role Do Robotics Play in Toyota’s Production?

Robotics play a significant role in Toyota’s production processes. Robots are used for various tasks, including welding, painting, assembly, and material handling, to enhance efficiency, improve quality, and reduce the risk of workplace injuries.

Toyota’s use of robotics also enables the company to produce vehicles more quickly and accurately, meeting the demands of a global market. By integrating robotics into its manufacturing operations, Toyota optimizes production processes and maintains its competitive edge.

7.2. How Is Automation Used in Toyota Manufacturing?

Automation is used extensively in Toyota manufacturing to streamline operations and improve efficiency. Automated systems are used for various tasks, including assembly, inspection, and quality control, to reduce human error and increase productivity.

Toyota’s use of automation also enables the company to produce vehicles more consistently and reliably, meeting the expectations of its customers. By embracing automation, Toyota enhances its manufacturing capabilities and delivers high-quality vehicles to the market.

7.3. How Does Toyota Use Data Analytics in Manufacturing?

Toyota uses data analytics in manufacturing to monitor and optimize production processes. Data analytics tools are used to track key performance indicators (KPIs), identify trends, and detect potential issues before they escalate.

Toyota’s use of data analytics also enables the company to make data-driven decisions, improve efficiency, and reduce costs. By leveraging data analytics, Toyota continuously enhances its manufacturing operations and delivers high-quality vehicles to its customers.

8. How Does Toyota Adapt to Changing Market Demands?

Toyota adapts to changing market demands through a flexible and responsive approach. This includes monitoring market trends, gathering customer feedback, and adjusting production plans to meet evolving needs.

Toyota’s adaptability also enables the company to stay ahead of the competition and maintain its leadership position in the global automotive market. According to Toyota’s annual reports, the company invests heavily in research and development to anticipate future market trends and develop innovative products and technologies.

8.1. What Is Toyota’s Approach to Market Research?

Toyota’s approach to market research involves gathering and analyzing data on customer preferences, market trends, and competitive dynamics. This information is used to inform product development, marketing strategies, and business decisions.

Toyota’s market research efforts also focus on understanding the needs and expectations of diverse customer segments, enabling the company to tailor its products and services to meet specific requirements. By conducting thorough market research, Toyota stays informed about changing market conditions and adapts its strategies accordingly.

8.2. How Does Toyota Use Customer Feedback?

Toyota uses customer feedback to improve its products and services. Customer feedback is collected through various channels, including surveys, focus groups, and online reviews.

Toyota’s use of customer feedback also enables the company to build stronger relationships with its customers and foster brand loyalty. By listening to its customers, Toyota continuously enhances its products and services to meet their evolving needs.

8.3. How Flexible Are Toyota’s Production Plans?

Toyota’s production plans are highly flexible, allowing the company to adjust production volumes and product mix in response to changing market demands. This flexibility is enabled by the Toyota Production System (TPS), which emphasizes lean manufacturing, just-in-time inventory management, and continuous improvement.

Toyota’s flexible production plans also enable the company to respond quickly to unexpected events, such as natural disasters or supply chain disruptions. By maintaining a flexible and adaptable approach to production, Toyota ensures that it can meet the needs of its customers and maintain its competitiveness in the global market.

9. What Is the Future of Toyota Manufacturing?

The future of Toyota manufacturing involves a continued focus on innovation, sustainability, and customer satisfaction. Toyota is investing in advanced technologies, such as electric vehicles, autonomous driving systems, and connected car technologies, to meet the evolving needs of its customers.

Toyota’s future plans also include expanding its global manufacturing footprint, strengthening its partnerships with suppliers, and enhancing its workforce development programs. By embracing innovation and sustainability, Toyota aims to remain a leader in the automotive industry and contribute to a better future for society.

9.1. What Innovations Are Toyota Pursuing?

Toyota is pursuing several key innovations to shape the future of its manufacturing operations. These include electrification, autonomous driving, connectivity, and advanced materials.

Toyota’s innovation efforts also focus on enhancing the customer experience, improving safety, and reducing environmental impact. By investing in these cutting-edge technologies, Toyota aims to remain at the forefront of the automotive industry and deliver innovative solutions to its customers.

9.2. How Is Sustainability Integrated into Future Plans?

Sustainability is fully integrated into Toyota’s future plans. The company has set ambitious goals for reducing carbon emissions, minimizing waste, and conserving resources across its entire value chain.

Toyota’s sustainability initiatives also include promoting the use of renewable energy, developing eco-friendly materials, and supporting biodiversity conservation. By prioritizing sustainability, Toyota aims to contribute to a cleaner, healthier planet and create a more sustainable future for society.

9.3. What Are Toyota’s Long-Term Manufacturing Goals?

Toyota’s long-term manufacturing goals include achieving zero emissions, eliminating waste, and creating a more sustainable and resilient supply chain. The company also aims to enhance the efficiency, flexibility, and responsiveness of its manufacturing operations to meet the evolving needs of its customers.

Toyota’s long-term goals also focus on fostering a culture of innovation, collaboration, and continuous improvement, empowering its workforce to drive positive change and create value for society. By pursuing these ambitious goals, Toyota aims to remain a leader in the automotive industry and contribute to a better future for generations to come.

10. Why Choose Miller Toyota in Boise, Idaho?

Choosing Miller Toyota in Boise, Idaho, means selecting a dealership that prioritizes customer satisfaction and provides a wide range of services to meet all your automotive needs. At millertoyota.net, you’ll find a comprehensive selection of new and used Toyota vehicles, expert service and maintenance, and a team of dedicated professionals ready to assist you.

Miller Toyota is dedicated to delivering exceptional value and building long-term relationships with our customers. We invite you to experience the Miller Toyota difference and discover why we are a trusted name in the Boise community. We focus on quality, reliability, and customer satisfaction.

10.1. What Toyota Models Are Available at Miller Toyota?

At Miller Toyota, you’ll find a wide variety of the latest Toyota models to suit your needs. From fuel-efficient sedans like the Toyota Camry and Corolla to versatile SUVs like the RAV4 and Highlander, and powerful trucks like the Tacoma and Tundra, we have something for everyone.

Each model offers the reliability, safety, and advanced technology that Toyota is known for. Visit millertoyota.net to explore our current inventory and find the perfect vehicle to match your lifestyle and budget. Our knowledgeable team is here to help you compare models, understand features, and make an informed decision.

10.2. What Services Does Miller Toyota Offer?

Miller Toyota offers a comprehensive range of services to keep your vehicle running smoothly. Our certified technicians provide expert maintenance and repair services, including oil changes, tire rotations, brake service, and more.

We also offer genuine Toyota parts and accessories to ensure the best performance and longevity for your vehicle. At millertoyota.net, you can easily schedule service appointments, order parts, and take advantage of our service specials. Our goal is to provide convenient, reliable, and affordable service to keep you on the road with confidence.

10.3. How Can I Contact Miller Toyota?

Contacting Miller Toyota is easy and convenient. You can reach us by phone at +1 (208) 376-8888 or visit our dealership at 208 N Maple Grove Rd, Boise, ID 83704, United States.

You can also visit millertoyota.net to explore our website, browse our inventory, schedule service, and connect with our team online. We are here to answer your questions, provide assistance, and help you with all your automotive needs. Contact us today to experience the Miller Toyota difference.

Ready to find your dream Toyota and experience top-notch service? Visit millertoyota.net now to explore our wide selection of vehicles, schedule a service appointment, and connect with our friendly team in Boise. Don’t miss out on our exclusive offers and discover why Miller Toyota is the preferred choice for Toyota enthusiasts.

Frequently Asked Questions (FAQ)

1. Where are Toyota vehicles primarily manufactured?

Toyota vehicles are manufactured in various locations globally, including Japan, the United States, and other countries.

2. Which Toyota models are made in the USA?

Several Toyota models are made in the USA, including the Camry, Tundra, Highlander, and Sequoia.

3. Where are Toyota manufacturing plants located in the USA?

Toyota’s manufacturing plants in the USA are located in Kentucky, Indiana, Texas, Mississippi, and Alabama.

4. How does Toyota ensure quality in its manufacturing processes?

Toyota ensures quality through the Toyota Production System (TPS), continuous improvement (Kaizen), and rigorous quality control processes.

5. What environmental practices does Toyota implement in its manufacturing?

Toyota focuses on reducing waste, conserving energy, minimizing water usage, and lowering emissions in its manufacturing operations.

6. What is the impact of Toyota manufacturing on local economies?

Toyota manufacturing creates jobs, stimulates economic growth, and supports local communities through various initiatives.

7. How does Toyota incorporate technology in its manufacturing processes?

Toyota incorporates robotics, automation, and data analytics to enhance efficiency, improve quality, and reduce costs in its manufacturing processes.

8. How does Toyota adapt to changing market demands?

Toyota adapts through market research, customer feedback, and flexible production plans to meet evolving needs.

9. What is the future of Toyota manufacturing?

The future involves a continued focus on innovation, sustainability, and customer satisfaction, with investments in electric vehicles, autonomous driving, and connected car technologies.

10. Why should I choose Miller Toyota in Boise, Idaho?

Miller Toyota offers a wide selection of new and used Toyota vehicles, expert service and maintenance, and a dedicated team committed to customer satisfaction.