Toyota’s journey to the top is paved with innovation and customer satisfaction; millertoyota.net is committed to providing you with the best Toyota experience in Boise. From fuel-efficient hybrids to reliable trucks, we have a Toyota for every need. Explore our website for the latest models, exceptional service, and special offers. Consider fuel economy, green technology, and vehicle quality for your needs.

1. What Were The Key Factors In Toyota’s Rise To The Top?

Toyota’s rise to the top can be attributed to a combination of factors including a focus on quality, reliability, and continuous improvement, also known as “Kaizen”. This dedication has solidified Toyota’s reputation for producing vehicles that are dependable, long-lasting, and offer excellent value. The brand’s strategic investments in hybrid technology, exemplified by the Prius, have further cemented its position as an industry leader in eco-friendly transportation. According to customer satisfaction surveys, Toyota consistently ranks high in owner satisfaction. This has helped build a loyal customer base. This reputation is evident at millertoyota.net, where we pride ourselves on offering vehicles that embody these qualities, along with exceptional customer service to match.

1.1 How Did Toyota’s Manufacturing Philosophy Contribute To Their Success?

The Toyota Production System (TPS) is a manufacturing philosophy that minimizes waste and maximizes efficiency, contributing significantly to Toyota’s success. This system emphasizes just-in-time production, ensuring that parts and materials arrive precisely when needed, reducing inventory costs and storage space. The TPS also empowers employees at all levels to identify and address issues, fostering a culture of continuous improvement. This leads to higher quality vehicles and more efficient production processes. This efficient process reflects Toyota’s dedication to quality. As stated on Toyota’s official website, TPS is a core element of their operational excellence.

1.2 What Role Did Innovation Play in Toyota’s Ascent to Market Leadership?

Innovation has been a cornerstone of Toyota’s journey to market leadership, with the company consistently pushing boundaries in automotive technology. Toyota’s pioneering work in hybrid technology, starting with the Prius, revolutionized the industry and positioned them as leaders in eco-friendly vehicles. Their commitment to research and development has also led to advancements in safety features, fuel efficiency, and overall vehicle performance. These innovations have not only attracted customers but also set new standards for the automotive industry. For example, Toyota’s investment in solid-state batteries has the potential to revolutionize electric vehicle technology and further solidify their leadership.

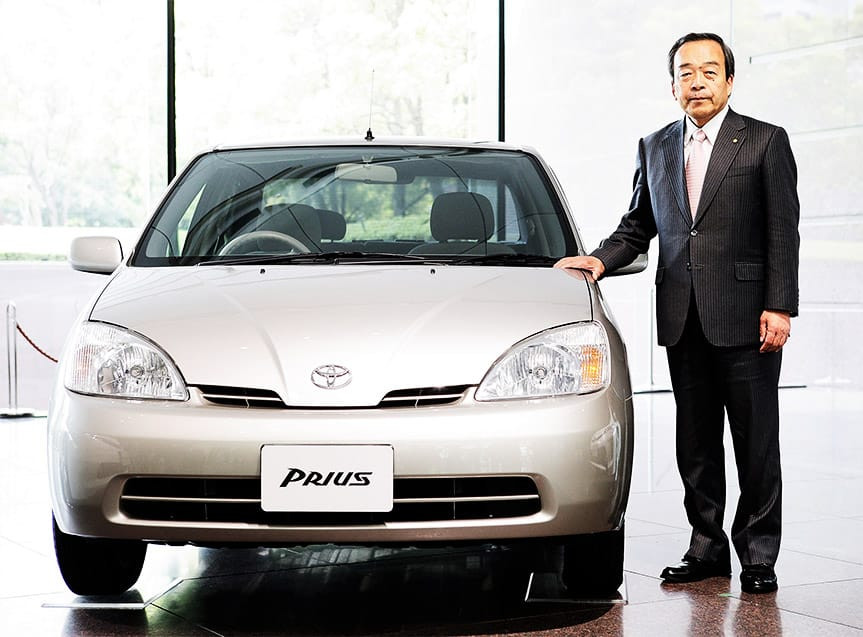

Satoshi Ogiso, member of every Prius development team since generation one

Satoshi Ogiso, member of every Prius development team since generation one

Ogiso, a long time member of Toyota’s team, contributed to the successful development of the Prius through innovation.

2. What Was The Significance Of The Toyota Prius In Shaping The Company’s Image?

The Toyota Prius played a pivotal role in shaping Toyota’s image as a forward-thinking and environmentally conscious automaker. As the world’s first mass-produced hybrid vehicle, the Prius demonstrated Toyota’s commitment to sustainability and innovation. Its fuel efficiency and reduced emissions appealed to a growing segment of environmentally aware consumers. This helped to differentiate Toyota from its competitors. The Prius became a symbol of Toyota’s dedication to creating vehicles that are not only reliable and affordable but also contribute to a cleaner environment.

2.1 How Did The Prius Impact Public Perception Of Hybrid Vehicles?

The Prius revolutionized public perception of hybrid vehicles, transforming them from niche products to mainstream choices. Its widespread adoption demonstrated that hybrid technology could be both practical and desirable. The Prius dispelled the myth that eco-friendly cars were underpowered or unattractive. It paved the way for other automakers to invest in hybrid technology. It also increased consumer demand for fuel-efficient vehicles. According to a study by the Union of Concerned Scientists, the Prius significantly reduced greenhouse gas emissions compared to conventional vehicles.

2.2 What Were The Key Technological Innovations Introduced With The Prius?

The Prius introduced several key technological innovations to the automotive industry, most notably the Toyota Hybrid System (THS). This system combines a gasoline engine with an electric motor to deliver exceptional fuel efficiency and reduced emissions. The Prius also featured regenerative braking. This captures energy during deceleration and recharges the battery. Other innovations included advanced electronic control systems and lightweight materials to further improve efficiency. These technologies not only made the Prius a success but also influenced the development of hybrid vehicles across the industry.

3. How Has The Toyota Production System (TPS) Contributed To Toyota’s Quality And Efficiency?

The Toyota Production System (TPS) has been instrumental in achieving exceptional quality and efficiency. TPS emphasizes the elimination of waste (muda) in all aspects of the production process, from inventory to motion. By implementing principles like just-in-time production and autonomation (jidoka), Toyota has been able to streamline its operations, reduce costs, and improve the quality of its vehicles. The TPS also fosters a culture of continuous improvement (kaizen). This empowers employees to identify and solve problems, leading to ongoing enhancements in efficiency and quality.

3.1 What Are The Core Principles Of The Toyota Production System?

The core principles of the Toyota Production System include:

- Just-in-Time (JIT): Producing goods only when they are needed, minimizing inventory and waste.

- Autonomation (Jidoka): Designing equipment to automatically detect defects and stop production, preventing defective products from moving further down the line.

- Continuous Improvement (Kaizen): Fostering a culture of ongoing improvement and innovation, encouraging employees to identify and implement small but impactful changes.

- Respect for People: Recognizing and valuing the contributions of all employees, empowering them to participate in problem-solving and decision-making.

- Waste Reduction (Muda): Identifying and eliminating all forms of waste in the production process, including overproduction, waiting, transportation, and defects.

3.2 How Does TPS Differ From Traditional Mass Production Systems?

TPS differs significantly from traditional mass production systems in its emphasis on flexibility, waste reduction, and employee empowerment. Traditional mass production systems typically focus on producing large quantities of standardized products, often resulting in high inventory levels and limited flexibility. TPS, on the other hand, prioritizes producing only what is needed, when it is needed, minimizing waste and allowing for greater customization. TPS also empowers employees to identify and solve problems, fostering a culture of continuous improvement, while traditional systems often rely on top-down management and limited employee input.

4. What Strategies Did Toyota Employ To Ensure High Levels Of Customer Satisfaction?

Toyota has consistently prioritized customer satisfaction through a variety of strategies. These include:

- Building High-Quality, Reliable Vehicles: Toyota’s reputation for producing durable and dependable vehicles is a key driver of customer satisfaction.

- Providing Excellent Customer Service: Toyota dealerships are known for their friendly, knowledgeable staff and commitment to providing a positive ownership experience.

- Offering Competitive Pricing: Toyota offers a range of vehicles at competitive prices, making them accessible to a wide range of customers.

- Listening to Customer Feedback: Toyota actively solicits and responds to customer feedback, using it to improve its products and services.

- Building a Strong Brand Reputation: Toyota has cultivated a strong brand reputation for quality, reliability, and value, which helps to attract and retain customers.

At millertoyota.net, we embody these strategies by offering a wide selection of Toyota vehicles, exceptional service, and a customer-focused approach.

4.1 How Does Toyota Use Customer Feedback To Improve Their Vehicles And Services?

Toyota places a high value on customer feedback and uses it extensively to improve its vehicles and services. The company gathers feedback through various channels, including customer surveys, online reviews, and direct communication with dealerships. This feedback is then analyzed to identify areas for improvement in vehicle design, features, and performance, as well as service processes and customer interactions. Toyota’s engineers and designers use this information to make data-driven decisions about product development and enhancements. This ensures that Toyota vehicles and services continue to meet and exceed customer expectations.

4.2 What Role Do Toyota Dealerships Play In Maintaining Customer Satisfaction?

Toyota dealerships play a critical role in maintaining customer satisfaction by providing a positive and seamless ownership experience. Dealerships are responsible for sales, service, and parts, serving as the primary point of contact for customers throughout their ownership journey. Toyota dealerships are trained to provide exceptional customer service, offering knowledgeable and friendly assistance with vehicle selection, financing, and maintenance. They also ensure that customers receive prompt and efficient service, using genuine Toyota parts and adhering to Toyota’s high standards of quality. At millertoyota.net, we are committed to upholding these standards and providing our customers with the best possible experience.

5. How Did Toyota Successfully Expand Its Market Share Globally?

Toyota’s successful global expansion can be attributed to a number of factors, including:

- Producing High-Quality, Reliable Vehicles: Toyota’s reputation for quality and reliability has resonated with customers around the world, helping to drive sales and market share.

- Adapting to Local Market Needs: Toyota has demonstrated a willingness to adapt its products and services to meet the specific needs and preferences of different markets.

- Building Strong Local Partnerships: Toyota has formed strategic partnerships with local companies and governments to facilitate its entry into new markets.

- Investing in Local Production: Toyota has invested in local production facilities in many countries, creating jobs and contributing to local economies, which has helped to build goodwill and support for the brand.

- Offering Competitive Pricing: Toyota offers a range of vehicles at competitive prices, making them accessible to a wide range of customers in different markets.

5.1 What Strategies Did Toyota Use To Adapt To Different Regional Markets?

Toyota has employed a variety of strategies to adapt to different regional markets, including:

- Conducting Market Research: Toyota conducts extensive market research to understand the specific needs and preferences of customers in different regions.

- Developing Region-Specific Models: Toyota develops models specifically tailored to the needs of different regions, such as the Toyota Hilux pickup truck, which is popular in many developing countries.

- Localizing Production: Toyota localizes production in many regions, using local suppliers and employees to reduce costs and create jobs.

- Adapting Marketing Campaigns: Toyota adapts its marketing campaigns to resonate with local cultures and values.

- Offering Region-Specific Financing Options: Toyota offers financing options tailored to the financial circumstances of customers in different regions.

5.2 How Important Were Joint Ventures And Partnerships In Toyota’s Global Expansion?

Joint ventures and partnerships have been crucial to Toyota’s global expansion, enabling the company to enter new markets more quickly and efficiently. By partnering with local companies, Toyota has been able to leverage their existing infrastructure, knowledge of the local market, and relationships with local suppliers and governments. Joint ventures have also allowed Toyota to share the risks and costs associated with entering new markets, making global expansion more feasible. These partnerships have been particularly important in regions with complex regulatory environments or strong local competitors.

Takeshi Uchiyamada, Chairman of Toyota Motor Corporation

Takeshi Uchiyamada, Chairman of Toyota Motor Corporation

Uchiyamada, the Chairman of Toyota Motor Corporation, has been crucial in leading the company to great success globally.

6. What Is The Significance Of “Kaizen” (Continuous Improvement) In Toyota’s Corporate Culture?

“Kaizen,” the Japanese term for continuous improvement, is a fundamental aspect of Toyota’s corporate culture. This philosophy emphasizes that every aspect of the company, from product development to manufacturing to customer service, can always be improved. Kaizen encourages employees at all levels to identify and implement small, incremental changes that lead to greater efficiency, quality, and customer satisfaction. This commitment to continuous improvement has helped Toyota to stay ahead of the competition and maintain its position as a leader in the automotive industry.

6.1 How Is “Kaizen” Implemented At All Levels Of The Organization?

Kaizen is implemented at all levels of the organization through a variety of mechanisms, including:

- Employee Empowerment: Toyota empowers employees to identify and implement improvements in their own work areas, providing them with the training and resources they need to succeed.

- Cross-Functional Teams: Toyota uses cross-functional teams to address complex problems and implement large-scale improvements.

- Suggestion Systems: Toyota encourages employees to submit suggestions for improvements, and rewards them for ideas that are implemented.

- Regular Audits: Toyota conducts regular audits of its processes and systems to identify areas for improvement.

- Training Programs: Toyota provides ongoing training to employees at all levels to help them understand and implement Kaizen principles.

6.2 What Are Some Examples Of “Kaizen” In Practice At Toyota?

Examples of Kaizen in practice at Toyota include:

- Improving Assembly Line Efficiency: Employees on the assembly line identify ways to streamline their work processes, reducing the time it takes to assemble a vehicle.

- Reducing Waste in Manufacturing: Employees identify and eliminate sources of waste in the manufacturing process, such as overproduction, waiting, and transportation.

- Enhancing Customer Service: Employees identify ways to improve the customer experience, such as reducing wait times or providing more personalized service.

- Improving Product Design: Engineers use customer feedback to identify areas for improvement in product design, such as increasing fuel efficiency or adding new features.

- Streamlining Administrative Processes: Employees identify ways to streamline administrative processes, such as reducing paperwork or automating tasks.

7. How Has Toyota Addressed Environmental Concerns And Promoted Sustainability?

Toyota has demonstrated a strong commitment to addressing environmental concerns and promoting sustainability through a variety of initiatives, including:

- Developing Hybrid and Electric Vehicles: Toyota has been a leader in the development of hybrid and electric vehicles, reducing emissions and improving fuel efficiency.

- Reducing Waste in Manufacturing: Toyota has implemented programs to reduce waste in its manufacturing processes, minimizing its environmental impact.

- Using Renewable Energy: Toyota has invested in renewable energy sources to power its manufacturing facilities.

- Promoting Recycling: Toyota promotes recycling of vehicles and parts, reducing the amount of waste that goes to landfills.

- Supporting Environmental Education: Toyota supports environmental education programs, raising awareness of environmental issues and promoting sustainable practices.

7.1 What Are Toyota’s Goals For Reducing Carbon Emissions?

Toyota has set ambitious goals for reducing carbon emissions, including:

- Reducing Vehicle Emissions: Toyota aims to reduce CO2 emissions from its vehicles by 90% by 2050, compared to 2010 levels.

- Achieving Carbon Neutrality: Toyota aims to achieve carbon neutrality in its global operations by 2050, reducing emissions from its manufacturing facilities, offices, and other operations.

- Promoting Sustainable Mobility: Toyota is promoting sustainable mobility solutions, such as car sharing and public transportation, to reduce overall carbon emissions from transportation.

7.2 How Is Toyota Investing In Electric Vehicle Technology?

Toyota is investing heavily in electric vehicle technology, including:

- Developing New Electric Vehicle Models: Toyota is developing a range of new electric vehicle models, including battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs).

- Improving Battery Technology: Toyota is investing in research and development to improve battery technology, increasing the range and performance of its electric vehicles.

- Building Charging Infrastructure: Toyota is working with partners to build charging infrastructure for electric vehicles, making it easier for customers to charge their vehicles.

- Promoting Electric Vehicle Adoption: Toyota is promoting the adoption of electric vehicles through marketing campaigns and incentives.

8. What Are The Challenges Toyota Faces In Maintaining Its Leadership Position?

Toyota faces a number of challenges in maintaining its leadership position, including:

- Increasing Competition: The automotive industry is becoming increasingly competitive, with new players entering the market and established players investing heavily in new technologies.

- Technological Disruption: The automotive industry is undergoing rapid technological change, with electric vehicles, autonomous driving, and connected car technologies transforming the way people drive and use vehicles.

- Changing Customer Preferences: Customer preferences are changing, with a growing demand for electric vehicles, SUVs, and connected car features.

- Economic Uncertainty: Economic uncertainty can impact consumer spending and demand for vehicles, making it difficult for Toyota to maintain its sales and profitability.

- Regulatory Changes: Regulatory changes, such as stricter emissions standards and safety regulations, can increase the cost of developing and manufacturing vehicles.

8.1 How Is Toyota Adapting To The Rise Of Electric Vehicles And Autonomous Driving?

Toyota is adapting to the rise of electric vehicles and autonomous driving through a variety of initiatives, including:

- Investing in Electric Vehicle Technology: Toyota is investing heavily in electric vehicle technology, developing new electric vehicle models and improving battery technology.

- Developing Autonomous Driving Systems: Toyota is developing autonomous driving systems, aiming to bring fully autonomous vehicles to market in the coming years.

- Partnering with Technology Companies: Toyota is partnering with technology companies to accelerate its development of electric vehicle and autonomous driving technologies.

- Adapting its Manufacturing Processes: Toyota is adapting its manufacturing processes to accommodate the production of electric vehicles and autonomous vehicles.

- Training its Workforce: Toyota is training its workforce to develop the skills needed to design, manufacture, and service electric vehicles and autonomous vehicles.

8.2 What Strategies Is Toyota Using To Stay Ahead Of The Competition?

Toyota is using a variety of strategies to stay ahead of the competition, including:

- Investing in Research and Development: Toyota is investing heavily in research and development, developing new technologies and improving its existing products and services.

- Focusing on Quality and Reliability: Toyota is committed to maintaining its reputation for quality and reliability, ensuring that its vehicles continue to meet and exceed customer expectations.

- Adapting to Changing Customer Preferences: Toyota is adapting to changing customer preferences, offering a range of vehicles that meet the diverse needs and tastes of its customers.

- Expanding its Global Footprint: Toyota is expanding its global footprint, entering new markets and increasing its presence in existing markets.

- Building Strong Relationships with its Stakeholders: Toyota is building strong relationships with its stakeholders, including its employees, customers, suppliers, and communities.

9. How Does Miller Toyota In Boise Embody Toyota’s Principles And Values?

Miller Toyota in Boise embodies Toyota’s principles and values by providing exceptional customer service, offering high-quality vehicles, and adhering to the highest standards of integrity and professionalism. We are committed to providing our customers with a positive and seamless ownership experience, from the moment they walk through our doors to the years they spend driving their Toyota. We also embrace Toyota’s commitment to continuous improvement, constantly seeking ways to enhance our processes, products, and services.

9.1 What Specific Services Does Miller Toyota Offer To Enhance The Customer Experience?

Miller Toyota offers a wide range of services to enhance the customer experience, including:

- A Wide Selection of New and Used Toyota Vehicles: We offer a diverse inventory of new and used Toyota vehicles, ensuring that customers can find the perfect vehicle to meet their needs and budget.

- Competitive Financing Options: We offer competitive financing options, making it easier for customers to purchase the Toyota of their dreams.

- Expert Service and Maintenance: Our certified technicians provide expert service and maintenance, ensuring that your Toyota stays in top condition.

- Genuine Toyota Parts: We use only genuine Toyota parts, ensuring the quality and reliability of your vehicle.

- A Comfortable and Convenient Dealership Environment: Our dealership is designed to be comfortable and convenient, with amenities such as free Wi-Fi, comfortable waiting areas, and shuttle service.

9.2 How Does Miller Toyota Contribute To The Local Boise Community?

Miller Toyota is committed to contributing to the local Boise community through a variety of initiatives, including:

- Supporting Local Charities: We support local charities through donations and sponsorships.

- Participating in Community Events: We participate in community events, such as parades and festivals.

- Providing Jobs and Economic Opportunities: We provide jobs and economic opportunities for local residents.

- Promoting Environmental Sustainability: We promote environmental sustainability through our operations and community outreach programs.

Visit us at 208 N Maple Grove Rd, Boise, ID 83704, United States. Call us at +1 (208) 376-8888 or visit our website at millertoyota.net today!

10. What Can We Learn From Toyota’s Success Story?

Toyota’s success story offers valuable lessons for businesses of all sizes and industries, including:

- The Importance of Quality and Reliability: Building a reputation for quality and reliability is essential for long-term success.

- The Power of Continuous Improvement: Embracing a culture of continuous improvement can lead to greater efficiency, innovation, and customer satisfaction.

- The Value of Customer Focus: Prioritizing customer needs and providing exceptional customer service is crucial for building loyalty and driving sales.

- The Importance of Adapting to Change: Being able to adapt to changing market conditions and customer preferences is essential for staying ahead of the competition.

- The Power of Collaboration: Building strong relationships with stakeholders, including employees, customers, suppliers, and communities, can create a competitive advantage.

10.1 How Can Businesses Apply Toyota’s Principles To Their Own Operations?

Businesses can apply Toyota’s principles to their own operations by:

- Focusing on Quality: Implementing quality control measures to ensure that products and services meet customer expectations.

- Embracing Continuous Improvement: Encouraging employees to identify and implement improvements in their own work areas.

- Prioritizing Customer Needs: Gathering customer feedback and using it to improve products and services.

- Adapting to Change: Monitoring market trends and adjusting business strategies accordingly.

- Building Strong Relationships: Fostering a culture of collaboration and respect among employees, customers, and suppliers.

10.2 What Are The Key Takeaways For Aspiring Business Leaders?

The key takeaways for aspiring business leaders from Toyota’s success story are:

- Lead with Vision: Set a clear vision for the company and inspire others to achieve it.

- Empower Employees: Empower employees to take ownership of their work and contribute to the success of the company.

- Focus on the Customer: Put the customer at the center of every decision.

- Embrace Innovation: Encourage innovation and experimentation.

- Never Stop Learning: Continuously seek new knowledge and insights.

Internal development of core technologies

Internal development of core technologies

Toyota strives to lead in core technology through internal development.

Ready to experience the Toyota difference? Visit millertoyota.net today to browse our inventory, schedule a service appointment, or contact our friendly team in Boise! We’re here to help you find the perfect Toyota and provide you with the exceptional service you deserve.

Frequently Asked Questions (FAQ) About Toyota’s Success

-

What is the Toyota Production System (TPS)? The Toyota Production System (TPS) is a manufacturing philosophy that minimizes waste and maximizes efficiency, contributing significantly to Toyota’s success.

-

How did the Toyota Prius impact the company’s image? The Toyota Prius played a pivotal role in shaping Toyota’s image as a forward-thinking and environmentally conscious automaker.

-

What is “Kaizen” and how does it contribute to Toyota’s success? “Kaizen,” the Japanese term for continuous improvement, is a fundamental aspect of Toyota’s corporate culture. This philosophy emphasizes that every aspect of the company can always be improved.

-

What strategies did Toyota use to expand its market share globally? Toyota’s successful global expansion can be attributed to a number of factors, including producing high-quality, reliable vehicles and adapting to local market needs.

-

How does Toyota address environmental concerns and promote sustainability? Toyota has demonstrated a strong commitment to addressing environmental concerns and promoting sustainability through a variety of initiatives, including developing hybrid and electric vehicles.

-

What are some of the challenges Toyota faces in maintaining its leadership position? Toyota faces a number of challenges in maintaining its leadership position, including increasing competition and technological disruption.

-

How is Miller Toyota in Boise embodying Toyota’s principles and values? Miller Toyota in Boise embodies Toyota’s principles and values by providing exceptional customer service, offering high-quality vehicles, and adhering to the highest standards of integrity and professionalism.

-

What specific services does Miller Toyota offer to enhance the customer experience? Miller Toyota offers a wide range of services to enhance the customer experience, including a wide selection of new and used Toyota vehicles and competitive financing options.

-

How can businesses apply Toyota’s principles to their own operations? Businesses can apply Toyota’s principles to their own operations by focusing on quality and embracing continuous improvement.

-

What are the key takeaways for aspiring business leaders from Toyota’s success story? The key takeaways for aspiring business leaders from Toyota’s success story are to lead with vision and empower employees.